Robotics Transforms Cell Therapy: Multiply Labs Drives Staggering 74% Cost Reduction, Unlocking Global Patient Access

Robotics Transforms Cell Therapy: Multiply Labs Drives Staggering 74% Cost Reduction, Unlocking Global Patient Access

Breakthrough partnership with Universal Robots transforms "artisanal" manufacturing, making personalized, life-saving cancer treatments affordable and widely available.

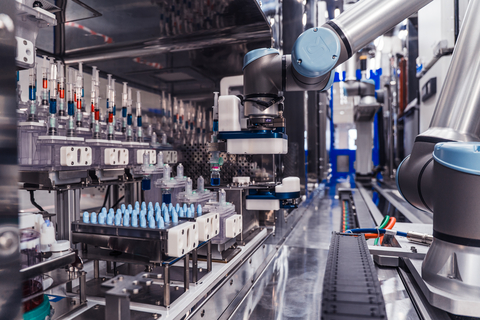

SAN FRANCISCO--(BUSINESS WIRE)--Multiply Labs, a pioneering robotics company, has developed a new robotic biomanufacturing cluster that achieves a 74% cost reduction for life-saving cell therapies. This breakthrough, published in peer-reviewed studies with UCSF, leverages collaborative robot arms from Universal Robots (UR), promising to transform how these complex treatments are produced. As UR’s first official partner in the cell and gene therapy sector, Multiply Labs’ robotically automated manufacturing processes will significantly expand patient access to therapies currently priced between $300,000 and $2 million per dose.

"This is a quantum leap in terms of being able to manufacture these medicines at a lower cost, and in a smaller space.”

Share

“Historically, cell and gene therapy manufacturing has been manual, almost artisanal," says Fred Parietti, CEO of Multiply Labs. "Expert scientists perform hundreds of tasks by hand, from pipetting to shaking cells." Unlike mass-produced drugs, personalized cell therapies, often used to treat blood cancers like lymphoma and leukemia, require a customized dose from each patient's own cells, making large-batch production impossible. A single microbial contamination renders the entire product unusable, leading to costly manufacturing failures.

A quantum leap in cell therapy manufacturing

Multiply Labs' modular ‘robotic biomanufacturing cluster’ features multiple UR robot arms working in parallel, stacked floor-to-ceiling with collision avoidance, handling the entire cell therapy manufacturing process. This system faithfully replicates manual processes with enhanced efficiency, repeatability, and sanitary conditions. Dr. Jonathan Esensten, Director of the Advanced Biotherapy Center at Sheba Medical Center (formerly UCSF faculty), collaborated with Multiply Labs to develop the robotic solution: “When we compared a traditional manual manufacturing process for these cell therapies to a robotic process doing the exact same process, we found a cost reduction of approximately 74%,” he confirms, adding: "Growing T cells is something that we have been doing for a long time, but to have the robotic system do it without any human hands touching the cells throughout the process, that is a quantum leap in terms of being able to manufacture these medicines at a lower cost, and in a smaller space.”

Up to 100x more patient doses per square foot of cleanroom

Beyond cost savings, the robotic system drastically improves space utilization, says Parietti, citing up to 100x more patient doses per square foot of cleanroom compared to a typical manual process. Quality and sterility are also significantly enhanced. "Robots don't breathe, and they don't touch stuff they're not supposed to touch," says the Multiply Labs CEO. The UCSF study confirms this: “While human handling led to contamination in one case, we did not see any contamination in the robotic process," says Dr. Esensten.

Imitation learning for process fidelity

A core innovation is Multiply Labs' ‘imitation learning’ technology, where robots learn from expert human demonstrations rather than dictating new processes. “We ask the pharmaceutical companies that we work with to videotape their scientists performing the tasks. We then feed this data to the robots, and the robots learn to effectively replicate what scientists were doing in the lab, just more efficiently, more repeatably, 24/7, and in parallel,” explains Parietti, emphasizing how this approach allows the UR robots to "self-learn hundreds of new tasks" with exponentially lower engineering costs. According to Dr. Esensten, this process fidelity is also crucial for regulatory compliance, potentially saving decades and billions of dollars in re-approval costs by replicating existing, already approved processes. “Instead of starting from square zero in terms of drug approval, companies can now document that this is the exact same manufacturing process. It just happens to be done by a robot.”

Universal Robots chosen after suites of tests

Multiply Labs chose Universal Robots for their robotics cluster after closely evaluating several different collaborative robots, says Head of Robotics at Multiply Labs, Nadia Kreciglowa: “UR was chosen due to their crucial six-axis capabilities, unrivaled force mode for delicate handling, seamless software integration, robust community support, and cleanroom compatibility.”

According to Jean-Pierre Hathout, President, Universal Robots, the new partnership illustrates the profound impact of collaborative automation in the healthcare space: “By empowering Multiply Labs to replicate intricate manual processes with high precision and scale, our cobots are redefining efficiency in pharmaceutical manufacturing,” he says, adding “More importantly, it’s driving significant cost reductions while broadening access to life-saving treatments. At its core, this partnership is a testament to how robotics can elevate human capability and serve critical needs in medicine.”

The Multiply Labs robotic cluster is already deployed in global pharmaceutical companies with results now also documented in collaboration with scientists at Stanford University. “This will really change the way we think about the manufacturing of these bespoke, custom cell and gene therapies for patients,” says Parietti. “We will ultimately improve patient access globally by lowering manufacturing costs, enabling distributed production worldwide of these life-saving therapies.”

Download images and captions: Media Kit

About Multiply Labs

Multiply Labs is a robotics company that provides autonomous manufacturing technology to the biomanufacturing industry. The company develops advanced, cloud-controlled robotic systems that enable the production of individualized drugs at scale. Its customers include some of the largest global organizations in the advanced pharmaceutical manufacturing space. Multiply Labs’ expertise is at the intersection of robotics and biopharma – its team includes mechanical engineers, electrical engineers, computer scientists, software engineers and pharmaceutical scientists. The company is based in San Francisco, California. www.multiplylabs.com

About Universal Robots

Universal Robots is a global leader in collaborative robotics (cobots), used across a wide range of industries. Our mission is simple: Automation for anyone. Anywhere. With over 100,000 cobots sold worldwide, our user-friendly platform is supported by intuitive PolyScope software, award-winning training, comprehensive services, and the world’s largest cobot ecosystem, delivering innovation and choice to our customers.

Universal Robots is part of Teradyne Robotics, a division of Teradyne (NASDAQ:TER), a leading supplier of automatic test equipment and advanced robotics technology, including Autonomous Mobile Robots (AMRs) from sister company Mobile Industrial Robots (MiR). For more information, please visit: www.universal-robots.com.

Contacts

Media Contact:

Mette McCall, McCall Media

mette@mccallmedia.net

+1 251 278 9847