Stratasys and Siemens Healthineers Bring a New Era for Medical Imaging Research With Patient-Specific 3D-Printed Phantoms

Stratasys and Siemens Healthineers Bring a New Era for Medical Imaging Research With Patient-Specific 3D-Printed Phantoms

Anatomically accurate 3D-printed phantoms replace cadavers, transforming CT imaging and AI algorithm training

EDEN PRAIRIE, Minn. & REHOVOT, Israel & ERLANGEN, Germany--(BUSINESS WIRE)--Stratasys Ltd. (NASDAQ: SSYS) and Siemens Healthineers recently presented the results of a joint research effort that demonstrates the unprecedented accuracy of the solutions offered by Stratasys to enable 3D-printed medical imaging phantoms to replicate human anatomy.

This collaborative effort uses Stratasys’ RadioMatrix™ materials and Digital Anatomy® technology with Siemens Healthineers’ advanced algorithms to significantly improve the quality of complex anatomy medical imaging phantoms, allowing surgeons, researchers, and educators to replace simplistic anatomical phantom models for pre-surgery planning and education.

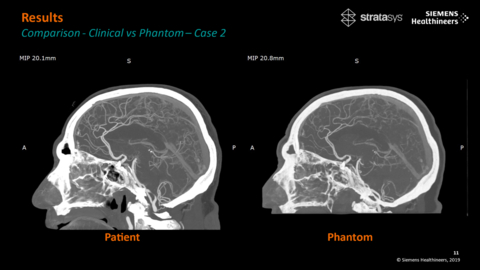

This new research demonstrates how anatomically accurate, patient-specific 3D-printed phantoms are scalable, cost effective and efficient in developing new CT scan algorithms and improving diagnostic precision. By using 3D-printed anatomic models for radiology, it is possible to offer a patient-specific, anatomical model that accurately replicates anatomy and pathologies.

"The integration of 3D-printing solutions to create patient-realistic CT phantoms, combined with the Digital Anatomy® technology from Stratasys, represents a significant innovation in the field of computed tomography,” said Jesús Fernández Léon, Head of Computed Tomography Product & Clinical Marketing at Siemens Healthineers. “This cooperation not only enhances our ability to assess and verify the performance of modern CT systems but also ensures that our algorithms can rely on a highly realistic depiction of human anatomy. By working together, we are setting new standards in medical imaging.”

The results of the study were shared during this winter’s Radiological Society of North America (RSNA) annual meeting.

The joint efforts will drive innovation in medical imaging through multiple ways:

- Integrating Stratasys’ advanced Digital Anatomy technology and materials with Siemens Healthineers’ imaging creates patient-specific phantoms with realistic radiopacity and anatomical precision. These models replicate clinical imaging outcomes more closely than existing traditional phantoms, addressing the radiology field’s long-standing need for consistency and reliability while preserving the anatomy and details of potential pathologies and/or variations of anatomy.

- With the ability to produce repeatable data sets on the same anatomy, these phantoms eliminate ethical, and variability challenges associated with human scans and/or the usage of cadavers.

- Advanced post-processing including validation data for AI-based software solutions. The ultra-realistic phantoms accelerate the development of imaging algorithms, driving materials innovation, and enabling the exploration of new clinical and academic applications.

By utilization of these kind of 3D-printed phantoms, hospitals and imaging centers can enhance the calibration and performance of CT scanners, ensuring more accurate diagnostics and better patient outcomes. These phantoms are also opening new doors for education, training, and research in radiology, ultimately improving patient outcomes and costs.

“The collaboration between Stratasys and Siemens Healthineers will pave the way for innovations that enhance imaging precision, improve training efficiency, and reduce reliance on cadavers,” said Erez Ben Zvi, Vice President of Healthcare, Stratasys. “This is a game-changer for the medical community. We believe this work can speed up the advancement of medicine and improve patient outcomes.”

The RSNA presentation also highlighted the significant deviations between real and printed models, with variances as low as single Hounsfield units (HU) in critical areas like grey matter and veins. This extraordinary level of accuracy redefines the standards for CT imaging research.

About Stratasys

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products, and healthcare. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys, visit www.stratasys.com, the Stratasys blog, X/Twitter, LinkedIn, or Facebook. Stratasys reserves the right to utilize any of the foregoing social media platforms, including Stratasys’ websites, to share material, non-public information pursuant to the SEC’s Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

Stratasys, Digital Anatomy and RadioMatrix are trademarks or registered trademarks of Stratasys Ltd. and/or its affiliates. All other trademarks are the property of their respective owners.

Contacts

Media Contacts:

Chris Reese

Stratasys

+1 651-357-0877

chris.reese@stratasys.com

Erik Snider

Stratasys

+1 952-906-8296

erik.snider@stratasys.com

Investor Relations:

Yonah Lloyd

Stratasys

+972 74 745 4919

yonah.lloyd@stratasys.com