CyberOptics Highlights the New SQ3000™+ Inspection and Metrology System at NEPCON Asia

CyberOptics Highlights the New SQ3000™+ Inspection and Metrology System at NEPCON Asia

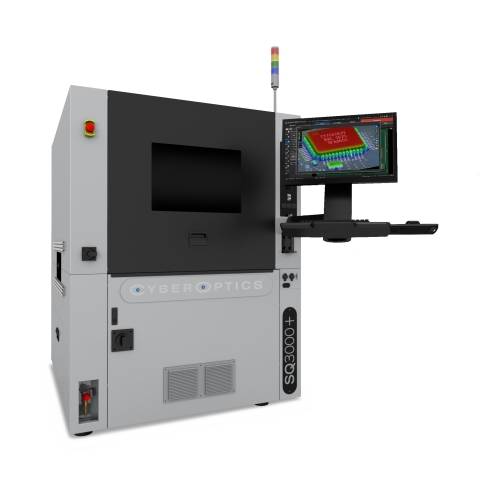

MINNEAPOLIS--(BUSINESS WIRE)--CyberOptics® Corporation (NASDAQ: CYBE), a leading global developer and manufacturer of high-precision 3D sensing technology solutions, will showcase its SQ3000™ Multi-Function system for AOI, SPI and CMM, and feature its new SQ3000™+ system for advanced applications at NEPCON Asia from Oct. 20-21, 2021 at the Shenzhen Convention Center, China in Booth #1J45.

The SQ3000+ is ideal for high-end applications including advanced packaging, mini-LED and advanced SMT for medical, military, aerospace and advanced electronics, 008004/0201 solder paste inspection (SPI), socket metrology and other advanced coordinate measurement (CMM) applications.

The SQ3000+ Multi-Function system for metrology and inspection is an extension of the multi-award-winning SQ3000 system platform deemed best-in-class. The new SQ3000+ offers a combination of unmatched high accuracy and high speed with an even higher resolution sensor.

The new, ultra-high resolution 5-micron Multi-Reflection Suppression™ (MRS™) sensor is specifically designed for advanced applications with stringent requirements. The proprietary MRS sensor technology incorporates highly sophisticated algorithms that meticulously identify and reject reflection-based distortions caused by shiny components and surfaces to deliver highly accurate measurements at production speeds.

“Next generation technologies are smaller, denser and more complex,” said Dr. Subodh Kulkarni, President and CEO, CyberOptics. “In order to maximize customer yields and improve processes, we have extended our MRS sensor portfolio to include an even higher resolution sensor designed specifically for these advanced applications.”

CyberOptics’ SQ3000 and SQ3000+ Multi-Function systems can identify critical defects and measure critical parameters, in order to fix what can be found and control what can be measured. In addition to AOI and SPI applications, highly accurate in-line coordinate measurements can be attained faster than a traditional Coordinate Measurement Machine (CMM) – in seconds, not hours.

Both systems include CyberCMM™, an extensive software suite for metrology grade measurements on all critical points, and the latest 3D AOI software that provides ultra-fast programming capabilities, including AutoTeach, AutoDefine and AutoTune that significantly speed setup, simplify the process, reduce training efforts and minimize operator interaction.

For more information, visit www.cyberoptics.com.

About CyberOptics

CyberOptics Corporation (www.cyberoptics.com) is a leading global developer and manufacturer of high-precision 3D sensing technology solutions. CyberOptics’ sensors are used for inspection and metrology in the SMT and semiconductor markets to significantly improve yields and productivity. By leveraging its leading edge technologies, the Company has strategically established itself as a global leader in high precision 3D sensors, allowing CyberOptics to further increase its penetration of key vertical markets. Headquartered in Minneapolis, Minnesota, CyberOptics conducts worldwide operations through its facilities in North America, Asia and Europe.

Statements regarding the Company’s anticipated performance are forward-looking and therefore involve risks and uncertainties, including but not limited to: a possible worldwide recession or depression resulting from the economic consequences of the COVID-19 pandemic; the negative effect on our revenue and operating results of the COVID-19 crisis on our customers and suppliers and the global supply chain; market conditions in the global SMT and semiconductor capital equipment industries; trade relations between the United States and China and other countries; the timing of orders and shipments of our products, particularly our 3D MRS SQ3000 Multi-Function systems and MX systems for memory module inspection; increasing price competition and price pressure on our product sales, particularly our SMT systems; the level of orders from our OEM customers; the availability of parts required to meet customer orders; unanticipated product development challenges; the effect of world events on our sales, the majority of which are from foreign customers; rapid changes in technology in the electronics and semiconductor markets; product introductions and pricing by our competitors; the success of our 3D technology initiatives; the market acceptance of our SQ3000 Multi-Function systems and products for semiconductor inspection and metrology; costly and time consuming litigation with third parties related to intellectual property infringement; the negative impact on our customers and suppliers due to past and future terrorist threats and attacks and any acts of war; the impact of the MX3000 orders on our consolidated gross margin percentage in any future period; risks related to cancellation or renegotiation of orders we have received; and other factors set forth in the Company’s filings with the Securities and Exchange Commission.

Contacts

Jeffrey A. Bertelsen,

Chief Financial Officer

763-542-5000

Carla Furanna

Vice President of Global Marketing

952-820-5837