Dairy Conveyor Corporation Recovers 600 Hours Through a Year of Optimizing Daily Tasks With the CADDi AI Data Platform

Dairy Conveyor Corporation Recovers 600 Hours Through a Year of Optimizing Daily Tasks With the CADDi AI Data Platform

Structured engineering data enables consistent reuse across engineering and procurement teams, reducing search time and improving workflow efficiency by 98 percent

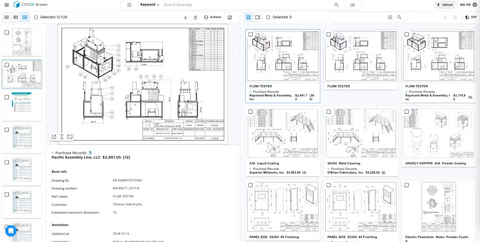

CHICAGO--(BUSINESS WIRE)--CADDi, a Chicago-based developer of manufacturing-exclusive AI data platforms designed to structure and reuse engineering designs and related information across engineering and procurement teams, today released a new customer case study detailing how Dairy Conveyor Corporation has benefitted from CADDi Drawer following a year of sustained operational use.

“By using CADDi Drawer, I have reduced my workflow time by over 80 percent. What once took an entire week can now be completed in a single afternoon, giving me more time to focus on other projects,” said Monica Merando, Director of Purchasing at DCC.

Share

At Dairy Conveyor Corporation, fragmented access to historical engineering drawings and related data limited the ability to consistently reuse prior work. By organizing that information into a shared, searchable knowledge foundation, engineering and procurement teams gained a more consistent way to search, compare, and reuse existing designs as part of normal operations.

After a year of continuous use, teams were able to reduce duplicate effort and reliance on manual searches. Over that period, the procurement team gained 600 working hours by reducing time on low-value tasks, with search and workflow efficiency improving by 98 percent.

A common challenge in engineer-to-order manufacturing

Since 1954, Dairy Conveyor Corporation has manufactured and distributed hygienic, performance-driven conveyor and automation systems for the dairy industry. Like many engineer-to-order manufacturers, the company accumulated tens of thousands of engineering drawings, purchasing records, and historical design information distributed across folders and systems over its decades of operation. While this information held operational value, it was difficult to locate and compare consistently during day-to-day work.

Dairy Conveyor Corporation addressed this challenge by using CADDi to organize historical engineering drawings and related records into a structured, searchable format. This enabled engineering and procurement teams to locate similar designs, review prior configurations, and reference historical information earlier in their workflows.

After a year of sustained use, the procurement team executed thousands of searches using CADDi, significantly reducing the time required to locate relevant information and supporting consistent reuse of existing engineering work.

According to Brian Thacker, Director of Customer Success at CADDi, “What we learned upon exploring DCC’s case is that what matters is not short-term deployment, but sustained use of the implemented technology. Maintaining access to existing engineering and purchasing data over time allows teams to continue moving faster and more accurately with information they already have.”

Engineering and procurement teams reuse historical information

With CADDi Drawer in regular use, Dairy Conveyor Corporation enables engineering and procurement teams to identify similar past designs, review historical documentation, and reference existing information earlier in project workflows.

“By using CADDi Drawer, I have reduced my workflow time by over 80 percent. What once took an entire week can now be completed in a single afternoon, giving me more time to focus on other projects,” said Monica Merando, Director of Purchasing at Dairy Conveyor Corporation.

CADDi provides a manufacturing intelligence platform focused on organizing and activating engineering data so it can be accessed during normal operational workflows. Through its product, CADDi Drawer, the company structures and indexes engineering drawings and related design information, allowing teams to search, compare, and reuse existing work during engineering and procurement activities. Sustained use ensures that historical engineering information remains accessible as projects accumulate and teams change.

The complete case study is available at us.caddi.com/case-studies

About CADDi

CADDi is an AI powered data platform that makes design and supply chain data accessible and actionable for manufacturing teams. Headquartered in Tokyo and Chicago, the company was founded in 2017 by industry veterans Yushiro Kato and Aki Kobashi, formerly of McKinsey, Apple, and Lockheed Martin. Its flagship product, CADDi Drawer, uses advanced AI to centralize and analyze unstructured design and production data, helping manufacturers improve efficiency, reduce redundancies, and unlock innovation. Recognized globally for innovation, CADDi was listed in Fast Company’s Most Innovative Companies and won the SaaS Award for Best Business Intelligence and Engineering Management Software. To learn more or to book a product demonstration, visit us.caddi.com.

Contacts

Media Contact

Milbien Medina

Senior Manager, Brand Marketing

CADDi USA

milbien_medina@caddi.com