As Global Heat Wave Buckles Traditional Roads, NVI Advanced Materials Group’s Polymer-Based Asphalt Additives Reduce High-Temperature Failures

As Global Heat Wave Buckles Traditional Roads, NVI Advanced Materials Group’s Polymer-Based Asphalt Additives Reduce High-Temperature Failures

ORLANDO, Fla.--(BUSINESS WIRE)--New Village Initiative’s Advanced Materials Group (“AMG”) has developed a highly engineered polymer asphalt additive that significantly reduces rutting and cracking.

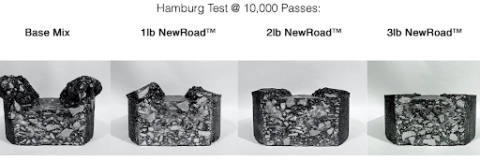

“NewRoad™ can reduce cracking by 20% and rutting by 50%,” says AMG President Mark Beeman. “These are important in preventing climate change-induced road damage.”

Industry standard Hamburg torture tests showed the durability of NewRoad™ over five years of testing in DOT, county and city roads as well as commercial projects.

Often, car dealerships and other businesses with heavy truck traffic find that conventional asphalt mixes develop cracking and deep rutting. NewRoad™ minimizes that damage and adding more of the product to the mix improves strength and performance even more.

In fact, Beeman says, NewRoad™ can increase tensile wet strength (TSR) by as much as 65%. Stronger mixes mean customers can use less asphalt, decreasing pavement thickness by as much as 35%. That can save money.

The innovative product is a lower-cost, better-performing alternative to fiber, or antistrip. And binder grade bumping lowers binder costs. Patent-pending NewRoad™ is engineered using recycled post-consumer and post-industrial plastic that makes each project “green” and lowers CO2 in the atmosphere.

The strength of the proprietary mixes also brings convenience. The product is easy to add at the plant. “NewRoad™ surfaces look great and last longer while reducing the carbon footprint of both asphalt and plastic use,” Beeman notes.

For more about NewRoad™ visit www.nviamg.com or email info@nviamg.com.

Contacts

Media Contact: Perry Beeman at info@nvi.amg.com