Boeing Qualifies Stratasys Antero 800NA Material for 3D-Printed Flight Parts

Boeing Qualifies Stratasys Antero 800NA Material for 3D-Printed Flight Parts

Enhanced chemical resistance and fatigue performance of the PEKK-based material over other alternatives provide Boeing with a new, high-performance option for polymer flight parts

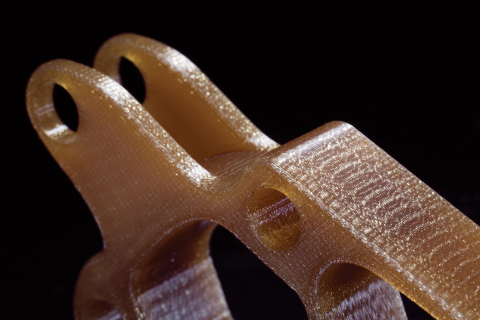

EDEN PRAIRIE, Minn.--(BUSINESS WIRE)--Boeing (NYSE: BA) has qualified the Antero 800NA thermoplastic to its repertoire of 3D printing capabilities, Stratasys Ltd. (NASDAQ: SSYS) announced today. The qualification means the high-temperature material can now be used on flight parts for Boeing planes.

Antero 800NA is a PEKK-based polymer developed specifically for production-grade Stratasys FDM® 3D printers. Boeing has released specification BMS8-444 and added the 800NA material to the Qualified Products List (QPL) after an extensive evaluation of the material’s performance. It is the first material from Stratasys qualified by Boeing for use in applications with elevated chemical resistance or fatigue requirements.

“Boeing has recognized the tremendous utility of Antero to meet applications that couldn’t have been 3D-printed before,” said Stratasys Aerospace Vice President Scott Sevcik. “Additive manufacturing has tremendous benefits for simplifying aerospace supply chains both in original equipment and MRO, but robust materials for meeting challenging flight requirements have been needed.”

The Antero family of materials includes 800NA as well as Antero 840CN03, which is an electrostatic dissipative (ESD) variant. Stratasys provides these materials both for customers who use the Stratasys F900 and Fortus 450mc 3D printers and as a material option for on-demand customers through Stratasys Direct Manufacturing.

Stratasys is a global leader in additive manufacturing or 3D printing technology and is the manufacturer of FDM®, PolyJet™, and stereolithography 3D printers. The company’s technologies are used to create prototypes, manufacturing tools, and production parts for industries, including aerospace, automotive, healthcare, consumer products and education. For more than 30 years, Stratasys products have helped manufacturers reduce product-development time, cost, and time-to-market, as well as reduce or eliminate tooling costs and improve product quality. The Stratasys 3D printing ecosystem of solutions and expertise includes 3D printers, materials, software, expert services, and on-demand parts production. Online at: www.stratasys.com.

To learn more about Stratasys, visit www.stratasys.com, the Stratasys blog, Twitter, LinkedIn, or Facebook. Stratasys reserves the right to utilize any of the foregoing social media platforms, including the company's websites, to share material, non-public information pursuant to the SEC's Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

Stratasys, FDM, and GrabCAD Print are trademarks of Stratasys Ltd. and/or its affiliates. All other trademarks are the property of their respective owners, and Stratasys assumes no responsibility with regard to the selection, performance, or use of these non-Stratasys products.

Attention Editors, if you publish reader-contact information, please use:

- USA +800-801-6491

- Europe/Middle East/Africa +49-7229-7772-0

- Asia Pacific +852 3944-8888

Contacts

Media Contacts

Stratasys Corporate & North America

Aaron Pearson

Aaron.pearson@stratasys.com

+1 612-716-9228

Europe, Middle East, and Africa

Jonathan Wake / Miguel Afonso, Incus Media

stratasys@incus-media.com

+44 1737 215200

Asia Pacific and Japan

Alice Chiu

alice.chiu@stratasys.com

+852-9189-7273

Investor Relations

Yonah Lloyd

Yonah.lloyd@stratasys.com

+972-74-745-4919

Brazil, Central America and South America

Erica.massini@stratasys.com

+55 (11) 2626-9229