ParaMatters 4.0 Generative Design Software Opens the Door for Digital and Traditional Manufacturers to Automate Design-to-Manufacturing Processes

ParaMatters 4.0 Generative Design Software Opens the Door for Digital and Traditional Manufacturers to Automate Design-to-Manufacturing Processes

Autonomous generative design platform offers structural and thermal design and analysis, support structures and build orientation optimization for the entire design to manufacturing process with an enhanced variety of loading conditions

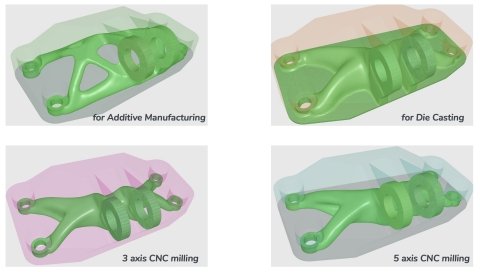

- Generative design for digital and traditional manufacturing featuring 3-axis and 5-axis CNC milling and die casting

- Advanced support structures providing optimal part orientation, robust generation of support structures, and fast slicing

- Hollowing and latticing capabilities

- Available in cloud and Windows desktop formats

VENTURA, Calif.--(BUSINESS WIRE)--ParaMatters, a leading generative design provider of autonomous topology optimization, parts consolidation and lightweighting software solutions, today announced the release of CogniCAD 4.0, a software upgrade that delivers a smooth and automated workflow from design to manufacturing for both digital and traditional manufacturers. ParaMatters 4.0 automatically generates ready-to-manufacture, high-performance, lightweighted structures for aerospace, automotive and other mission critical applications.

To learn more about what’s new in ParaMatters 4.0, check out this media kit and watch this video.

ParaMatters CogniCAD 4.0 gives engineers and designers the flexibility to generate effective designs using a wide range of manufacturing options, including the use of additive manufacturing, 3-axis and 5-axis CNC milling, and investment and die casting. Version 4.0 provides more robust and faster solvers which enhance vibration and stress constraints design with more control over geometry and manufacturing, like multi-plane symmetry constraints and accurate feature size. It offers a new advanced support structures generator to help designers and engineers prepare files for 3D printing, and optimal part orientation, fast slicing and hollowing for investment casting with new features for latticing and gyroids to enable greater efficiency while saving on materials for prototyping.

"With ParaMatters 4.0, both digital and traditional manufacturers can take advantage of this powerful agnostic CAD-to-CAD generative design and lightweighting software," said ParaMatters Co-founder and Chief Technology Officer Dr. Michael Bogomolny. “Traditional manufacturers now have access to a one-of-a-kind technology that enables them to create lightweighted and structurally validated parts to meet their design and manufacturing needs. Designers and engineers can automatically generate high-performance designs that consider various manufacturing technologies and make decisions based on a cost, performance and time-to-market basis.”

CogniCAD 4.0 works by first importing CAD files into the platform, and then defining loading, design and manufacturing criteria. Within tens of minutes, users can obtain generative designs verified by built-in, finite-element analysis, ready for 3D printing in both STL/PLY and STEP formats. All ParaMatters-generated designs can be directly produced using additive manufacturing and can also be transferred to traditional manufacturing processes.

CogniCAD 4.0 is available at www.paramatters.com as an annual subscription cloud-based service or as an annual local installation lease using a Windows-based installation. The company is offering several subscription and enterprise-based models, and actively engages in several complementary strategic partnerships.

ParaMatters continues to develop advanced algorithms designed to enhance the overall digital thread, and additive and traditional manufacturing capabilities. This includes a cloud-based, generative design platform that automatically compiles lightweight and metamaterial lattice structures on-demand, based on size, weight, strength, style, materials and cost as specified by designers or engineers.

About ParaMatters

ParaMatters is the leader in autonomous topology optimization and generative lightweighting design. The company's cloud-based cognitive design platform is capable of automatically generating additive and traditional manufacturing ready, high-performance, lightweighted structures for aerospace, automotive and other mission critical applications. ParaMatters is committed to transforming the entire design-to-manufacturing process by making it autonomous and automated to generate high quality, optimized lightweighted designs and additive manufactured structures. For more information, visit www.paramatters.com.

Contacts

Josh Turner

Silicon Valley Communications

turner@siliconvpr.com

+1-917-231-0550