Brightmark Wants Your Plastic: Launches Largest Ever Solicitation for Plastic Waste

Brightmark Wants Your Plastic: Launches Largest Ever Solicitation for Plastic Waste

Company to deploy proven, breakthrough closed loop solution for converting all types of plastic waste into sustainable fuels, plastics and other high value products

SAN FRANCISCO--(BUSINESS WIRE)--Brightmark, the global waste solutions provider, today announced that it is launching the largest ever solicitation for plastic waste and will deploy its proven, breakthrough circular solution for converting all types of plastic waste into sustainable fuels and other high value products.

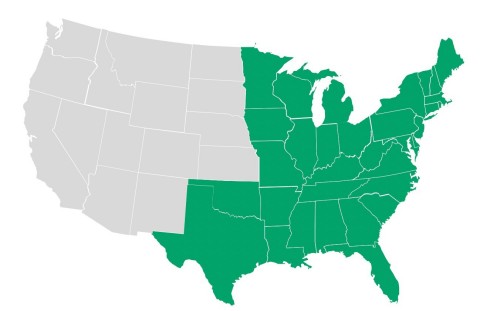

The company is working to procure more than 1,200,000 tons per year of post-use plastic types 1 through 7 from the Eastern half of the United States for recycling at its existing and soon-to-be-built plastics renewal plants nationwide. Brightmark’s call for plastics represents the company’s ability to provide a solution for a recycling industry that faces the end of plastic exports and the disruption of curbside collection programs nationwide following the COVID-19 pandemic.

Brightmark’s first advanced plastic recycling plant, serving the broader Midwest market, located in Northeast Indiana, is now in testing and will bring the facility to production-scale early next year. The company is in the final phases of determining the locations of its next recycling facilities in Florida, Georgia, New Jersey, New York, Pennsylvania, Louisiana, or Texas. Brightmark plans to make its final site selection decisions by the fourth quarter of this year and have at least two sites shovel-ready by 2021.

“Brightmark is on a mission to reimagine waste and wants your difficult-to-recycle plastics – and we want all of them,” said Brightmark CEO Bob Powell. “Plastics 3-7, in particular, are not easily recycled with other technologies, and typically end up in landfills, incinerators, or sadly – in our oceans. We’re proud to have a proven, breakthrough closed loop solution for transforming these raw materials back into useful products.”

Brightmark’s proprietary plastics renewal technology takes single-stream, post-use plastics and converts them into ultra-low sulfur diesel, naphtha, and wax, at a scale never achieved before. The process is also capable of creating the building blocks for new plastics, thus enabling a circular economy in the plastics industry. To date, the company has successfully disrupted particularly challenging waste streams, including boat shrink wrap, e-waste, and children’s car seats.

“This is a challenging moment for recycling in the United States, but those challenges are now being met with innovation by companies like Brightmark,” said Brightmark’s Chief Development Officer Zeina El-Azzi. “We’re rising to this challenge and calling on materials recovery facilities and waste collection companies to reach out to us today about how we can help to alleviate the overwhelming supply of plastic waste they’re facing.”

Brightmark anticipates that its next phase of advanced plastic recycling projects will be operational by 2023, and these facilities will process a minimum of 400,000 tons of post-use plastics each year. The company is developing hubs for materials collection throughout the Eastern United States, which will gather and bale materials for shipping to its recycling plants.

“Our partnership with Brightmark has enabled us to dramatically increase the amount of materials we can accept for processing,” say Gregg Keesling, President of RecycleForce, a social enterprise organization that trains formerly incarcerated individuals for jobs in the recycling industry. “They’re taking 1,700 tons per month of our plastics from televisions, computers, car seats, hospitals and other products. And now that we have a consistent customer for those materials, we can train, hire, and help more people.”

Interested suppliers must be able to provide a minimum of 1,000 tons of feedstock per year, and should reach out to Brightmark via this form to learn more about the opportunity. Suppliers must be contracted with the company by November 15, 2020.

ABOUT BRIGHTMARK

Brightmark is a global waste solutions company with a mission to reimagine waste. The company takes a holistic, closed loop, circular economy approach to tackling the planet’s most pressing environmental challenges with imagination and optimism for the future. Through the deployment of disruptive, breakthrough waste-to-energy solutions focused on plastics renewal (plastic waste-to-fuel) and renewable natural gas (organic waste-to-fuel), Brightmark enables programs specifically tailored to environmental needs in order to build scalable project solutions that have a positive impact on the world and communities in which its stakeholders live and work. For more information, visit www.brightmark.com.

Contacts

Cory Ziskind

ICR

Cory.Ziskind@icrinc.com

646-277-1232