Xerion’s DirectPlate™ Critical Minerals Refinement Technology Named to TIME’s List of the Best Inventions of 2025

Xerion’s DirectPlate™ Critical Minerals Refinement Technology Named to TIME’s List of the Best Inventions of 2025

DirectPlate™ creates a one-step metal refining technique from impure mined raw materials and select recycling streams, positioning Xerion to dramatically reshape global critical material supply chains

Xerion has achieved pilot scale production of 99% purity refined cobalt metal at its Dayton, OH facility

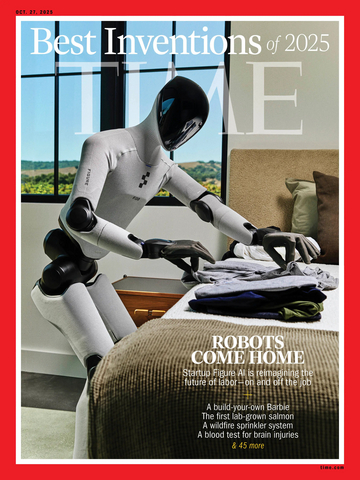

DAYTON, Ohio--(BUSINESS WIRE)--Xerion Advanced Battery Corp. (“Xerion” or “the Company”), a disruptive developer and manufacturer of next-generation battery components and critical minerals, is honored to announce the selection of its DirectPlate™ critical minerals refinement technology to TIME’s list of the Best Inventions of 2025. Selection to this list, which features 300 extraordinary innovations changing our lives, serves as a reflection of the growing awareness of the need to advance domestic critical mineral supply chains, as well as the significant potential Xerion’s DirectPlate™ presents for the reshaping of the United States' approach to securing essential critical minerals and battery materials.

“Stemming from my time serving in the military, I understand firsthand the critical importance of supply chain security to our national defense and economic prosperity,” said Dr. John Busbee, CEO, Xerion Advanced Battery Corp. “This recognition by TIME for our DirectPlate™ technology is not just an honor for Xerion, it's validation of our mission to strengthen America's strategic position in critical minerals. We are proud to be working to reduce America’s reliance on foreign suppliers for critical minerals like cobalt and gallium, which are essential to our ability to manufacture defense systems, electric vehicles, semiconductors, and medical devices.”

Xerion’s proprietary DirectPlate™ technology, originally developed for the refining and synthesis of battery components, introduces a single-step, continuous process that dramatically reduces the complexity and cost of cobalt refinement. This process offers significant advantages over legacy refinement methods relative to unit economics, supply chain security, and environmental impact. The Company has begun pilot-scale cobalt refinement, consistently achieving greater than 99% pure cobalt metal output with greater than 98% yields, at its Dayton, OH facility. Additionally, Xerion recently announced an expansion of its DirectPlate™ critical minerals refinement portfolio with the recent demonstration of the capability to refine gallium.

Critical minerals are essential to the US economy and national security, yet the US relies on convoluted supply chains for many of the key minerals it needs for defense and commercial applications. Today, the US possesses zero domestic cobalt refinement capacity, while China is responsible for 72% of global refinement capacity, according to the International Energy Agency (IEA). Similarly, over 98% of global gallium refinement is concentrated in China, and in December, 2024 China implemented a ban on exports of gallium and germanium to the United States, creating a single-point-of-failure risk for the United States and its allies. The advancement of domestic critical mineral refinement capabilities offers significant opportunities to secure supply chains for key industries ranging from defense and aerospace to semiconductors and next-generation batteries.

To compile this year's list, TIME solicited nominations from TIME editors and correspondents around the world, and through an online application process, paying special attention to growing fields—such as health care and AI. TIME then evaluated each contender on a number of key factors, including originality, efficacy, ambition, and impact.

See the full list here: time.com/collections/best-inventions-2025/

About Xerion Advanced Battery Corp.

Founded in 2010, Xerion Advanced Battery Corp. is a developer and manufacturer of next-generation battery components and critical minerals with a vision to revolutionize the energy industry through disruptive innovations. Xerion's proprietary technologies, including its DirectPlate™ critical metals refining and deposition technique and StructurePore™ battery electrode architecture, enable step-change performance improvements in lithium-ion batteries while strengthening domestic critical materials supply chains. Through these core technologies, Xerion delivers solutions that address national security challenges while providing fundamental improvements across the battery supply chain, from mineral refinement through to end-user applications, with enhanced performance and reduced environmental impact.

Contacts

Investors Contact:

Dr. John Busbee CEO

John.Busbee@xerionbattery.com

(217) 377-6888

Jim Thompson CFO

Jim.thompson@xerionbattery.com

(248) 513-2267

Martin Rucidlo COO

m.rucidlo@xerionbattery.com

513-310-3460

Media Contact:

Xerion@icrinc.com