SATO CL4NX Plus and CL6NX Plus to Feature Recycled Plastics from Konica Minolta

SATO CL4NX Plus and CL6NX Plus to Feature Recycled Plastics from Konica Minolta

Cutting emissions by 65% demonstrates commitment to sustainability through innovation

TOKYO--(BUSINESS WIRE)--SATO Corporation, a global pioneer in auto-ID and labeling solutions, is excited to announce a new collaboration with Konica Minolta, Inc., as it will now build its flagship CL4NX Plus and CL6NX Plus printers using recycled plastics that Konica Minolta has developed for its multifunctional printers. SATO’s industrial printers made from recycled materials will soon be available on the market.

Product development at SATO adheres to eight principles (see below) it defines as SATO universal printer design, which expresses its commitment to creating printers that offer equitable use, reliable operation and lasting quality. Its products support multiple languages and function regardless of the workplace environment and available infrastructure.

SATO’s collaboration with Konica Minolta is a new step toward environmental stewardship, which is integral to SATO universal printer design. SATO currently offers linerless labels as part of its efforts to use resources sustainably and reduce carbon emissions, but it now takes this commitment further by incorporating recycled plastics into select printer models starting FY 2024.

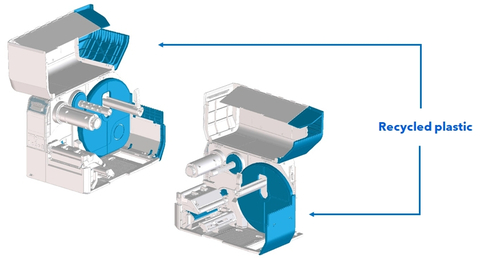

Konica Minolta’s recycled plastics meet SATO’s stringent quality standards for flame retardancy, flexural strength, density and mold shrinkage rate. The recycled plastics are used in 40 percent of the housing components of CL4NX Plus and CL6NX Plus, and SATO expects to reduce carbon emissions by 65 percent1 in parts where recycled plastic is used, compared to conventional parts without compromising the quality that virgin materials provide. Using recycled plastics in its flagship printers sold worldwide not only supports SATO’s global sustainability efforts but also allows its customers to contribute to reducing carbon emissions.

The material developed by Konica Minolta is a recycled ABS plastic,2 a flame-retardant, durable and easy-to-mold synthetic resin. Used in Konica Minolta’s multifunctional printers, these plastics are collected from used game machines that are separated, dismantled, crushed and washed. The processed material is then melted and compounded into plastic pellets for horizontal recycling.

In line with our corporate mission, SATO will seek ever more sustainable manufacturing practices by incorporating recycled materials in our products.

Models with recycled plastic

CL4NX Plus, CL6NX Plus (Global models)

CL4NX-J Plus, CL6NX-J Plus (Japan models)

SATO Universal Design principles

- Equitable use

- Flexibility in use

- Simple and intuitive

- Perceptible information

- Tolerance for error

- Low physical effort

- Size and space for approach and use

- Eco-friendliness

| 1. | SATO survey |

| 2. | Acrylonitrile Butadiene Styrene or ABS, is used for the housing and ergonomic parts of appliances and daily use products like keyboards and more. |

- All company names and product names here are properties and trademarks or registered trademarks of their respective owners.

About SATO

SATO (TOKYO:6287) designs and manufactures hardware, labels and tags and develops software to integrate with third party offerings as automatic identification solutions. These solutions streamline workflows, enabling data capture and visualization for a connected world of productivity, safety, reassurance and sustainability. By giving things a digital identity, SATO helps businesses in retail, manufacturing, food, health care and transport & logistics run smoothly. Founded in 1940, SATO has a presence in 26 countries with a workforce of over 5,700. For the fiscal year ended March 31, 2024, it reported revenues of 143,446 million yen ($992 million*)

More information about SATO can be found at www.sato-global.com

*Based on an average exchange rate of 1 USD = 144.58 JPY

Contacts

Media contact:

Kevin Leidheiser

SATO Holdings Corporation Public Relations

+81 80 2097 0683

kevin.leidheiser (at) sato-global.com