Asahi Kasei develops novel membrane system to dehydrate organic solvents without heat or pressure – Contributing to process optimization in the pharmaceutical industry

Asahi Kasei develops novel membrane system to dehydrate organic solvents without heat or pressure – Contributing to process optimization in the pharmaceutical industry

DÜSSELDORF, Germany & TOKYO--(BUSINESS WIRE)--Asahi Kasei has developed a novel membrane system for dehydrating organic solvents for pharmaceutical applications without the application of heat or pressure. This system can contribute to the optimization of manufacturing processes in the pharmaceutical industry. The company has now begun collaborating with Ono Pharmaceutical Co., Ltd., of Osaka, Japan, for the practical verification of this system.

Used to dissolve active ingredients and intermediates, organic solvents play an essential role in the manufacturing process of pharmaceuticals. To achieve the desired results in various process such as reactions and crystallization, such solvents need to be dehydrated. Standard dehydration methods such as vacuum distillation require the application of heat. These methods are not only time- and energy-intensive, but may also have undesired effects on the pharmaceutical intermediates contained in the organic solution, especially those which are sensitive to heat.

Asahi Kasei is a global manufacturer of membranes which are utilized in various industries, including virus removal filters and water treatment membranes.

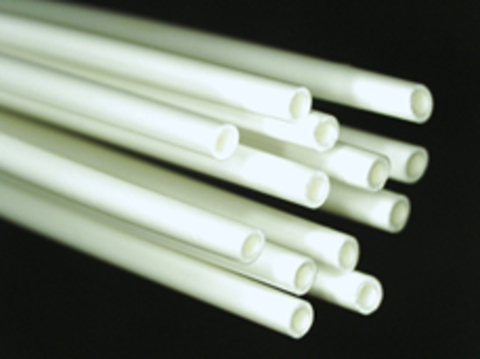

Asahi Kasei has now further leveraged its expertise to develop a novel dehydration membrane system including a hollow-fiber module and draw solution for organic solvents in the pharmaceutical manufacturing process. This system utilizes the phenomenon of osmosis, in which a liquid moves through a semipermeable membrane due to concentration differences. The development of the forward osmosis membrane and the draw solution enables the removal of water without the loss of intermediates.

Being able to handle highly soluble liquids such as tetrahydrofuran (THF), toluene or methanol, this membrane system can dehydrate organic solvents below 1,000 ppm without applying heat or pressure, thereby minimizing the impact on heat-sensitive pharmaceutical intermediates. In addition, compared to the conventional technology of vacuum distillation, the process time required can be shortened and energy consumption can be significantly reduced. The membrane system can be used with a variety of organic solvents, including alcohols, ethers, esters, and hydrocarbons.

To evaluate the performance of the membrane system in practical use, Asahi Kasei is collaborating with Osaka-based Ono Pharmaceutical. Commercialization is targeted for 2027.

About Asahi Kasei

The Asahi Kasei Group contributes to life and living for people around the world. Since its founding in 1922 with ammonia and cellulose fiber businesses, Asahi Kasei has consistently grown through the proactive transformation of its business portfolio to meet the evolving needs of every era. With more than 48,000 employees worldwide, the company contributes to a sustainable society by providing solutions to some of the world’s toughest challenges through its three business sectors: Material, Homes, and Health Care. For more information, visit https://www.asahi-kasei.com/.

Asahi Kasei is also dedicated to sustainability initiatives and is contributing to reaching a carbon-neutral society by 2050. To learn more, visit https://www.asahi-kasei.com/sustainability/.

Contacts

Company Contact Europe:

Asahi Kasei Europe GmbH

Sebastian Schmidt

Fringsstrasse 17, 40221 Düsseldorf

Tel: +49 (0) 211-3399-2058

E-mail: sebastian.schmidt@asahi-kasei.eu