Prometheus Materials’ Bio-Cement and Bio-Concrete Achieves 12x the Sound Absorption of Traditional Concrete in ASTM Testing

Prometheus Materials’ Bio-Cement and Bio-Concrete Achieves 12x the Sound Absorption of Traditional Concrete in ASTM Testing

This latest accomplishment joins the company’s previously secured ASTM certifications, enhancing the features and expanding the end-uses for its microalgae-based bio-cement and bio-concrete.

BOULDER, Colo.--(BUSINESS WIRE)--Prometheus Materials, a leader in sustainable building materials, announced today the achievement of remarkable results in the ASTM C423 sound-absorption testing of its ground-breaking bio-cement and bio-concrete technology. The company develops revolutionary zero-carbon building solutions that provide a superior alternative to carbon-intensive portland cement.

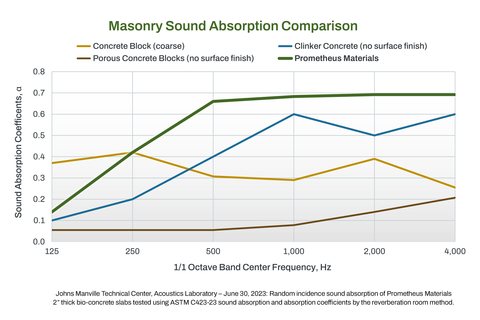

The Johns Manville Technical Center in Littleton, Colorado – a world-class research and development facility – conducted the independent testing, which found that Prometheus Materials’ bio-concrete demonstrated a Noise Reduction Coefficient (NRC) of 0.60. This NRC rating indicates 60% sound absorption – twelve times that of traditional concrete.

Prometheus Materials’ initial pre-cast bio-concrete product line includes masonry units, segmented modular block and acoustic panels – where this exceptional sound-absorption characteristic will be an essential feature – as well as paving stones and grass pavers. These products are currently available strictly for select projects, with commercial availability slated for the first half of 2024.

Such unrivaled sound absorption is a cost-saving, environment-enhancing boon for various sectors. In settings where noise can be damaging or distracting, builders are often forced to rely on secondary products to achieve some measure of noise reduction. Beyond the added expense, these materials can sometimes have negative effects – including health risks. However, with Prometheus Materials’ bio-cement and bio-concrete products, such facilities can incorporate sound-absorption capabilities without additional cost, safety concerns or other drawbacks. Residential, commercial and institutional buildings, amphitheaters, music studios, highway barriers – and a vast array of other end-uses – will all benefit from this exceptional noise-reduction capability, while concurrently reducing their carbon footprint.

“Our latest ASTM testing results embody our commitment to innovative design,” said Loren Burnett, President, CEO & Co-founder of Prometheus Materials. “We’ve developed a novel material that provides a zero-carbon alternative to traditional concrete while delivering additional performance benefits and applications. We’re proud to pave the way toward a more technologically advanced and environmentally responsible future for the construction industry.”

Vishaan Chakrabarti, FAIA FRAIC – renowned architect, academic and business leader with focus on sustainable design; Founder and Creative Director of Practice for Architecture & Urbanism (PAU); and member of Prometheus Materials’ Board of Directors – was equally inspired. “Test results like these prove that Prometheus Materials has developed far more than zero-carbon concrete – which by itself is an enormous accomplishment,” he said. “With this level of sound absorption, as well as other characteristics currently being tested, it's clear that this material will offer a suite of products based on entirely redefined ideas of what concrete can be and do.”

Prometheus Materials continues to lead the charge in sustainability and innovation within the building materials sector. With these ASTM C423 sound-absorption results joining its previously secured ASTM C129 and C90 certifications – plus other features of its bio-cement and bio-concrete that are comparable or superior to traditional concrete – the company is poised to drive the construction industry toward a more cutting-edge and sustainable future.

About Prometheus Materials

Prometheus Materials provides sustainable building materials that accelerate the world’s transition to a carbon-negative future. Inspired by biological processes found in nature, the company’s process uses microalgae to produce a bio-cement that offers an alternative to carbon-intensive portland cement. When mixed with aggregate, this bio-cement forms a zero-carbon bio-concrete with mechanical, physical and thermal properties that rival those of portland cement-based concrete. Learn more about how the company enables the decarbonization of the construction industry at prometheusmaterials.com.

Contacts

Liz Crumpacker

Antenna Group

prometheus@antennagroup.com