ASPINA Announces AMR Solutions

ASPINA Announces AMR Solutions

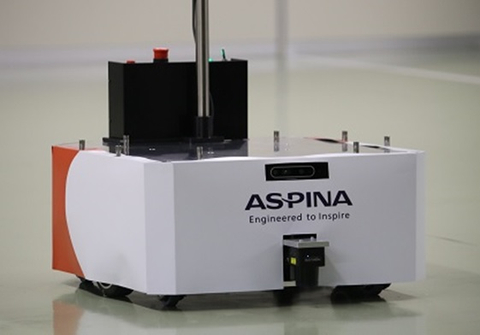

CULVER CITY, Calif.--(BUSINESS WIRE)--ASPINA announces the development of an Autonomous Mobile Robot (AMR) that supports labor-saving transportation for manufacturing plants.

ASPINA has developed an Autonomous Mobile Robot (AMR) which can be easily integrated for use on a manufacturing plant floor and is developed from insight of its own manufacturing experiences for the past 100 years. This robot has realized short-term introduction (automatic mapping), guideless (autonomous driving), and quick turning with body and leg movements.

The AMR is equipped with Simultaneous Localization and Mapping (SLAM) function which enables the factory map to be automatically created by simply running within the actual driving location. It can easily enter narrow passes with quick movement and can be operated with your existing plant floor layouts. In addition, it can be easily synched with other automated equipment features in your facility, e.g. automatic doors.

This is a total solution by ASPINA for the manufacturing industry or other sectors where goods mobility is needed. Its quick learning of floor layouts provides seamless integration from 1st time use. With its SLAM feature, you can implement with workplace safety confidence as ASPINA’s AMR coexists with workers and other transportation equipments.

Scalability, easy implementation and flexibility comes with AMR

AMR with autonomous driving capability makes it possible to introduce to existing manufacturing lines with complex and non-static stations. The Autonomous Mobile Robot easily maneuvers among changing environments without the need to re-program or map new paths (labor and cost savings!).

ASPINA will be promoting their AMR product on trial basis starting in July 2022, with limited number of units. As a build-to-order product, we will first meet to understand your needs and then plan together the use of AMR in your facility.

In the manufacturing industry, carrying operations, such as the delivery of parts to the manufacturing process and the transportation of finished products, are necessary operations that always occur, but in many cases they are recorded as indirect expenses and are not included in product estimates. By automating transportation, we can reduce costs and improve productivity. In other words, the labor saving of transport automation is a very effective means of directly improving corporate profits.

Automated Guided Vehicles (AGV) and AMR (see comparison table below) are attracting attention as means of automating transportation and lowering costs. However, unlike automated warehouses and fully automated processes, manufacturing sites often change their layouts. In production sites and processes where workers and transport equipment coexist in a limited space, where there is daily movement, and safety is of utmost importance, the following issues arise.

AGV Challenges

- Taking too many trials/time to set up.

- The size and movement do not meet the requirements of the site to be introduced.

ASPINA AMR Features

- User Interface Usability

- Basic hardware performance for the manufacturing sites

About ASPINA

Established in 1918, ASPINA develops and produces motors and modules in fields such as industrial equipment, home appliances, housing, automobiles, medical care, and welfare. We constantly refine our technology for realizing elements of compact, lightweight, and quiet. In addition to mastering the movement of goods, we work together with our partners to touch the hearts of our end users. Both sales staff and engineers take the initiative to talk to customers to solve problems and make proposals. Our slogan “Engineered to Inspire” incorporates our desire to use technology to create a new future for the world and to touch the hearts of people.

ASPINA Incorporated

- U.S. Headquarters: Culver City, CA

- Website: us.aspina-group.com/en

- CEO: Rex Bergsma

- Organization: Privately owned

- Founded: 1918

#Hashtags

#ASPINA

Social Media:

LinkedIn: https://www.linkedin.com/company/aspina-america

Contacts

Marcel Azary

(310) 908-4064

mazary@shinano.com