EDEN PRAIRIE, Minn. & REHOVOT, Israel--(BUSINESS WIRE)--Stratasys Ltd., a leader in polymer 3D printing solutions, today announced two new PolyJet™ 3D printers, the Stratasys J35™ Pro and the Stratasys J55™ Prime, along with new software solutions for research and packaging prototyping.

Stratasys has accelerated its pace of innovation using PolyJet technology as designers and engineers work to bring new and better products to market faster and more efficiently. The J35 Pro represents the first multi-material 3D printer for the desktop from Stratasys, while the J55 Prime extends the value of the J55 3D printer to include a new set of versatile materials providing tactile, textual, and sensory capabilities in addition to full color.

“We’re in the business of helping designers and engineers translate whatever they can imagine into reality,” said Shamir Shoham, vice president of design for Stratasys. “Through the versatility of multi-material PolyJet 3D printing, our customers can create models and packaging prototypes not only quickly and efficiently, but with remarkable realism that stands out against other 3D printing technology.”

J35 Pro Brings Multi-Material PolyJet Printing to the Desktop at Affordable Prices

The new versatile J35 Pro 3D printer accommodates everything from concept modeling to high-fidelity, realistic, fully functioning models. This new all-in-one, multi-material desktop 3D printer is ideal for the engineering and design office setting. With the J35 Pro, users have the option to combine a variety of materials, including Vero™ UltraClear, that can be printed simultaneously giving engineers and designers the versatility to produce parts that match their exact needs. The printer can incorporate up to three materials that can be printed as single material parts or combined on the same model part, on the same tray. Applications include over-molding, filling simulation and printing in full grey scale.

“We find that we spend a great deal of time creating and testing models. If a customer had changes or if it doesn’t work as expected, we would have to go through the process over again. By bringing the J35 Pro into our office, we can now create the models and prototypes in-house, in a day – giving us the ability to iterate, correct errors and more efficiently verify designs with our customers,” said Yaniv Adir project manager for Taga Innovations, Ltd, a manufacturing engineering company in Tel Aviv, Israel. “This printer has allowed us to revolutionize the way in which we do business.”

The multi-material capabilities of the printer allow designers and engineers to incorporate the widest variety of grayscale colors and materials into a single print, while achieving complex shapes, intricate details, and delicate features. Engineers and designers can not only see what the product will look like, but also test the functionality of it in the pre-production stage. The J35 Pro also offers a simple design-to-print workflow powered by GrabCAD Print™, allowing users to import their designs using native CAD files or 3MF file formats.

The J35 Pro is available for orders today and is expected to begin shipping in September. Click here to learn more.

Packaging Visual Prototypes you won’t Believe are 3D Printed

The new packaging solution from Stratasys enables designers to easily produce complex, high-transparency, full-color, high-fidelity packaging prototypes that accurately simulate final packaging including realistic color combinations, textures, transparency, and flexibility. This includes the ability to print simulated glass bottles and add “labels” with sharp text and images that meet 2D graphics labeling standards. Furthermore, designers can incorporate simulated products or fillings, like cosmetics, makeup or liquids, for the ultimate in realistic rapid prototyping. Designers can now create packaging prototypes so real-looking, it’s hard to believe they’re not the real thing.

“Ultra-realistic models make the idea real for our clients, enabling an accelerated decision-making process. We are a long way from the bland all-white models we produced prior to 3D printing – today the possibilities are endless,” said Jeremy Garrard, director of design and advanced technologies for Quadpack, a global packaging provider. “Along with our customers, the models we produce go a long way in terms of influencing and inspiring the industry. As an example, we printed over 500 pieces for #QPPackfuture, our annual trend report, in which the Design and Advanced Technology team presents its vision for the future of cosmetics packaging, complete with samples.”

The Packaging software solution will soon be available through GrabCAD Print and is compatible with Stratasys J8™ Prime, Stratasys J7 Series™ and Stratasys J55™ Prime 3D printers. To learn more about how PolyJet technology can take packaging prototypes to the next level, visit www.stratasys.com/packaging.

J55 Prime Extends Prototyping Possibilities

The J55 Prime builds on the technology of the Stratasys J55™ 3D printer introduced in 2020. This new system goes beyond full-color printing with new materials that enable tactile, textual, and sensory capabilities. In addition to the existing highly realistic visual models, the printer utilizes multiple materials that cater to design, functional and biocompatible prototyping, such as:

- Elastico™ Clear and Elastico™ Black for flexible, soft-touch printing that accurately simulates the look, feel and function of rubber-like products.

- Digital ABS™ Ivory for high impact designs such as molds, jigs, fixtures and functional prototypes.

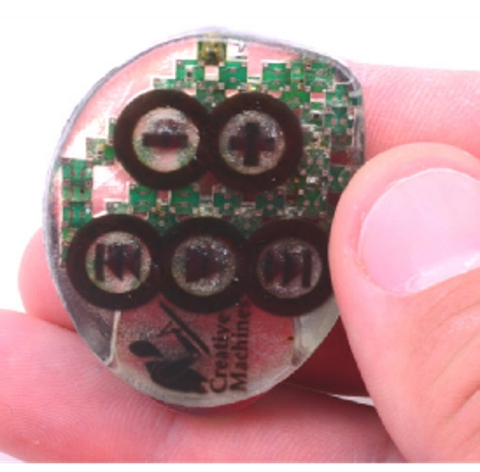

- Vero™ContactClear, a translucent material designed for prolonged skin or bodily contact such as medical devices, sport wear, or wearables.

- Ultra-opaque colors, enabled by the VeroUltra™ family of materials, introduces 2D level graphics and text, vibrant and accurate colors with better plastic simulation, raising the bar in 3D printed multi-material models.

The J55 Prime is office-friendly, with a compact design, odor-free and quiet operation; orders are being taken now, with shipping expected in July 2021. For more information, visit the J55 Prime webpage.

Researchers Accelerate Innovation with the Power of PolyJet

The research package provides users with increased flexibility over the print process, allowing them to explore and experiment with additive manufacturing and accelerate innovation in the lab. Innovators can now use the materials to print with air voids and liquid or embed an object into a print. Truly pushing the boundaries of what is possible, researchers can also use this extended set of materials and capabilities to experiment with 4D printing – the process by which a 3D printed object undergoes a transformation due to the influence of another material or outside element Combined with GrabCAD Voxel Print™, software users can define the data volumetrically for each 3D voxel throughout the entire model. This allows for an advanced level of control at a microscopic scale, enabling higher resolutions, fine-tuned color placement and shore value transitions within one part.

Click here to read how Dr. MacCurdy, assistant professor of robotics and systems design at the University of Colorado, is using PolyJet printing capabilities in his lab.

The PolyJet Research Package is available for booking now and is expected to be released in September 2021. To learn more about unlocking the power of innovation though Stratasys software solutions, visit www.stratasys.com/software.

To learn more about Stratasys’ ability to bring your design realities to life, visit www.stratasys.com/realism.

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products and healthcare. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys, visit www.stratasys.com, the Stratasys blog, Twitter, LinkedIn, or Facebook.

Stratasys, J55, J35, J8, J7 Series, PolyJet, GrabCAD Print, GrabCAD Voxel Print trademarks or registered trademarks of Stratasys Ltd. and/or its affiliates. All other trademarks are the property of their respective owners, and Stratasys assumes no responsibility with regard to the selection, performance, or use of these non-Stratasys products.

Note Regarding Forward-Looking Statement

The statements in this press release, including those related to Stratasys’ beliefs regarding the benefits consumers will experience from using the Stratasys J55 Prime, J35 Pro and packaging software and the expected shipping dates for such offerings are forward-looking statements reflecting management's current expectations and beliefs. These forward-looking statements are based on current information that is, by its nature, subject to rapid and even abrupt change. Due to risks and uncertainties associated with Stratasys' business, actual results could differ materially from those projected or implied by these forward-looking statements. These risks and uncertainties include, but are not limited to: the degree of our success at introducing new or improved products and solutions that gain market share; the degree of growth of the 3D printing market generally; the duration of the global COVID-19 pandemic, which, if extensive, may continue to impact, in a material adverse manner, our operations, financial position and cash flows, and those of our customers and suppliers; the impact of potential shifts in the prices or margins of the products that we sell or services that we provide, including due to a shift towards lower-margin products or services; the impact of competition and new technologies; potential further charges against earnings that we could be required to take due to impairment of additional goodwill or other intangible assets; to the extent of our success at successfully consummating acquisitions or investments in new businesses, technologies, products or services; potential changes in our management and board of directors; global market, political and economic conditions, and in the countries in which we operate in particular (including risks related to the impact of coronavirus on our operations, supply chain, liquidity, cash flow and customer orders; costs and potential liability relating to litigation and regulatory proceedings; risks related to infringement of our intellectual property rights by others or infringement of others' intellectual property rights by us; the extent of our success at maintaining our liquidity and financing our operations and capital needs; the impact of tax regulations on our results of operations and financial condition; and other risk factors set forth under the caption “Risk Factors” in Stratasys’ most recent Annual Report on Form 20-F, filed with the Securities and Exchange Commission (SEC) on March 1st, 2021. Readers are urged to carefully review and consider the various disclosures made throughout our 2020 Annual Report and our other reports filed with or furnished to the SEC, which are designed to advise interested parties of the risks and factors that may affect our business, financial condition, results of operations and prospects. Any guidance provided, and other forward-looking statements made, in this press release are made as of the date hereof, and Stratasys undertakes no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as required by law.

Attention Editors, if you publish reader-contact information, please use:

- USA +800-801-6491

- Europe/Middle East/Africa +49-7229-7772-0

- Asia Pacific +852 3944-8888