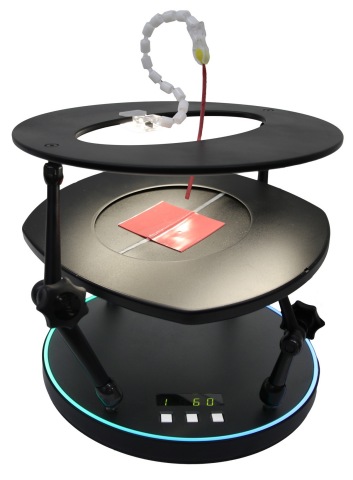

KIYOSU, Japan--(BUSINESS WIRE)--Toyoda Gosei Co., Ltd. and EBM Corporation1 have developed a prototype “Super BEAT” surgical training simulator that can reproduce the beating of the heart with extreme accuracy using e-Rubber,2 an artificial muscle that functions with electricity.

As medical surgeries become more and more sophisticated, ensuring safety becomes increasingly important. In specialties such as cardiovascular surgery, training using simulators becomes compulsory and demand for surgical training simulators is rapidly growing. Toyoda Gosei and EBM began collaborating in November 2017 to develop and promote a simulator that helps surgeons to efficiently improve their surgical skills.

In EBM’s current BEAT simulator, the movement of the heart is simulated with the use of a shape-memory alloy that expands and contracts by heating3. The Super BEAT high end version of this simulator uses e-Rubber, which expands and contracts rapidly in response to electricity switching on and off. Regulation of fine movement is also possible to mimic states such as complex heartbeat patterns due to arrhythmia or the rapid heartbeat of children, allowing reproduction of an environment closer to that of actual surgery.

About 20 cardiac surgeons participated in a workshop at EBM’s FIST surgical training center in Fukushima City, Fukushima Prefecture, Japan on June 30. Coronary artery bypass surgery simulator training was conducted using Super BEAT in the workshop. Professor Hitoshi Yokoyama of Fukushima Medical University performed this simulator training and was very impressed with the Super BEAT.

Toyoda Gosei and EBM aim to begin sales of Super BEAT in the fall of 2019, and are working to further improve its performance.

| 1 | EBM is a university-launched startup (established in 2006) involved in training simulator development and system creation for both domestic Japanese and overseas markets, principally in the field of cardiac surgery. Two of their main products, the BEAT and YOUCAN coronary bypass surgical training simulators, are used in about 70% of cardiovascular surgery hospitals in Japan. These simulators are also sold in the United States, Europe, and Asian countries. With the aim of international standardization of surgical technique training, EMS develops products based on a system of close cooperation with doctors from the aspects of both equipment and practices, centered on their “FIST” surgical training center. | |

| 2 |

A next-generation rubber that functions with electricity and mechanical force. Toyoda Gosei is developing this material for commercialization as soft actuators and soft sensors, with support from New Energy and Industrial Technology Development Organization in Japan. Using a supramolecular material (Slide Ring Material), it achieves a performance with high durability and low loss (low hysteresis loss) that is difficult with conventional dielectric actuators. |

|

|

3 |

A shape-memory alloy is a material that can be deformed when heated and recover its original shape when cooled. |

|

About Toyoda Gosei

Established in 1949 and headquartered in Kiyosu, Aichi Prefecture, Japan, Toyoda Gosei is a leading specialty manufacturer of rubber and plastic automotive parts. Today, the Toyoda Gosei Group provides a variety of high-quality products internationally, with a network of approximately 100 plants and offices in 18 countries and regions. Through its flexible, integrated global supply system and leading-edge technologies, Toyoda Gosei aims to grow as a global company that acts flexibly and swiftly in today’s dramatically changing business environment, delivering the highest levels of satisfaction to customers worldwide through safety, comfort, well-being and the environment.