WOBURN, Mass.--(BUSINESS WIRE)--OSSIO, Inc., a fast-growing orthopedic fixation technology company, announced today the U.S. launch and first commercial use of OSSIOfiber® Suture Anchors, expanding patient access to the company’s growing portfolio of bio-integrative implants for use in foot/ankle, shoulder, knee, hand/wrist and elbow surgery.

Gregory Berlet, M.D., founding partner at Orthopedic Foot and Ankle Center in Columbus, Ohio, recently became the first surgeon to use the new implant in clinical practice.

“The new OSSIOfiber Suture Anchors provide amazing strength and biology that I trust to be predictable and safe for my patients,” Dr. Berlet, chief medical officer of OSSIO, said. “Utilizing OSSIO’s trusted bio-integrative material, these anchors allow me to maintain my preferred technique for soft tissue fixation procedures while improving my results. This is another big step for OSSIOfiber in becoming a new material standard in orthopedic fixation.”

OSSIOfiber Suture Anchors were FDA cleared in March 2022 for use in “fixation of suture (soft tissue) to bone in the shoulder, foot/ankle, knee, hand/wrist, and elbow” in a variety of specific orthopedic procedures. These implants were designed to achieve unrivaled strength and unmatched safety using their proprietary OSSIOfiber Intelligent Bone Regeneration Technology that leaves nothing permanent behind.

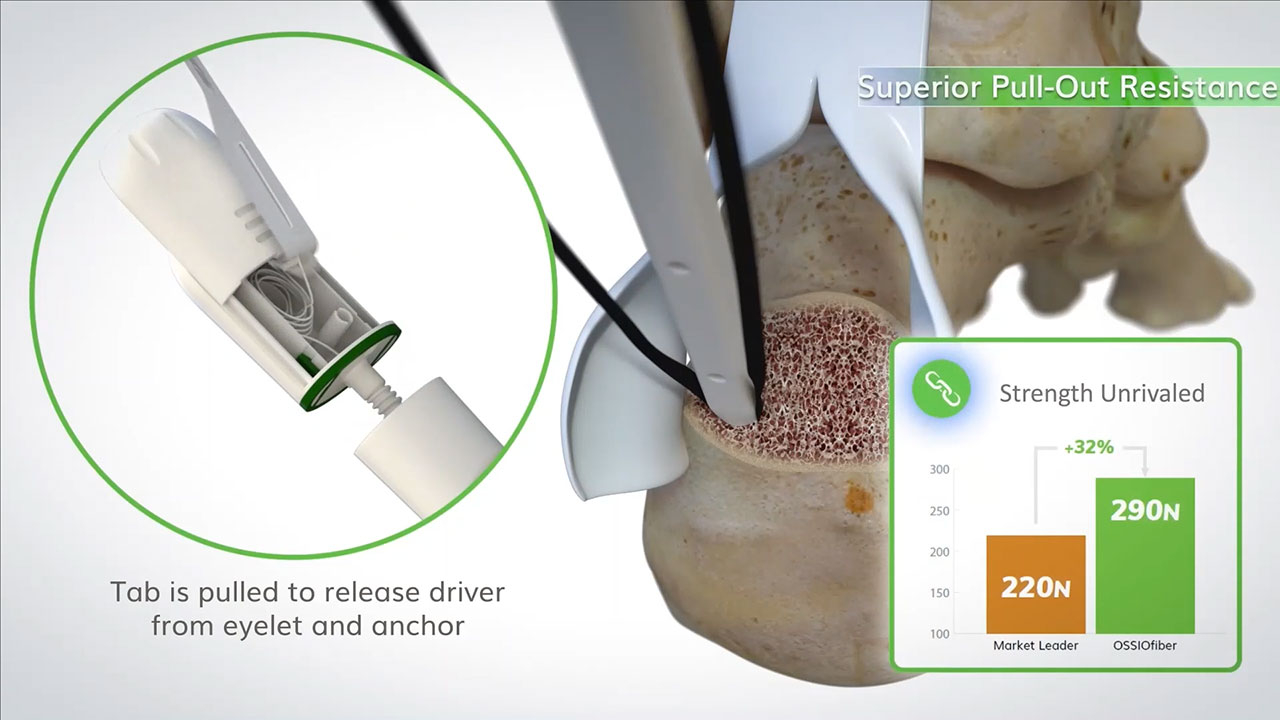

Additionally, the anchor’s proprietary DURAlinkTM Coupling Technology acts to increase stability and prevent suture slippage by connecting the eyelet to the anchor, creating a single stable unit. OSSIO will initially launch the 4.75mm system into the foot and ankle market, followed by the company’s first entry into the sports/shoulder markets later this year.

“The OSSIOfiber 4.75 Suture Anchor represents a substantive breakthrough in soft-tissue-to-bone fixation,” said Frank Petrigliano, M.D., chief of the University of Southern California Epstein Family Center for Sports Medicine in Los Angeles. “The implants can be utilized for a broad array of sports medicine procedures, and demonstrate strong, predictable bio-integration. This technology provides a biocompatible option that achieves excellent fixation without concern for implant fracture or incomplete integration into host bone. I look forward to using the OSSIOfiber 4.75 suture anchor for my sports and shoulder cases.”

OSSIO CEO Brian Verrier added: “Expanding our commercialized portfolio of OSSIOfiber implants, as well as patient access to additional bio-integrative solutions, is mission critical for the company’s continued success, and the launch of our suture anchors mark a significant milestone in that effort. Sports and extremity surgeons have been asking for non-permanent suture anchors that deliver improved strength and pull-out resistance, while providing safe, predictable bio-integration. OSSIOfiber Suture Anchors have shown strength that is unrivaled and safety that is unmatched in the market, as demonstrated by our bench testing and 30 month in-life studies compared to currently marketed bio-composite anchor controls.”

“Additionally,” Verrier said, “our products offer enhanced ease of use due to the incredible insertion strength of our continuous mineral fiber-based platform. We are excited to offer our customers a suture anchor that provides confidence during the healing process while avoiding many of the late issues sometimes seen in traditional suture anchors.”

About OSSIOfiber Intelligent Bone Regeneration Technology

All OSSIO implants are made with OSSIOfiber Intelligent Bone Regeneration Technology, a breakthrough in fixation material that provides the first credible solution to the shortcomings of permanent metal hardware, conventional resorbable and allograft implants, combining unparalleled mechanical strength and natural bone healing in a non-permanent implant. Made from a proprietary mineral fiber matrix held together by a naturally degradable polymer, its bio-integrative material properties provide surgeons with a more biologically friendly way to restore patient stability and mobility while leaving nothing permanent behind.

Designed for rapid bone in-growth, regeneration and replacement, OSSIOfiber Intelligent Bone Regeneration Technology is a first-of-its-kind implant material stronger than cortical bone. OSSIOfiber is engineered to provide the strength required for functional fixation and allows for full integration into the native anatomy without adverse biological response. OSSIOfiber implants utilize existing reimbursement and surgical techniques.

OSSIOfiber Intelligent Bone Regeneration Technology can address many surgical applications through the manufacturing of endless implant designs, including nails, screws, staples, anchors and plates. The company intends to pursue multiple applications in the distal extremity, trauma, sports, reconstruction, pediatrics and spine segments. For more information on OSSIOfiber implants, please visit www.ossio.io.

About OSSIO

OSSIO is an orthopedic fixation company committed to transforming the orthopedic experience for patients, physicians and payors. Founded in 2014, its vision is to provide the first credible replacement to metal implants in the multibillion-dollar global orthopedic fixation market with its OSSIOfiber Intelligent Bone Regeneration Technology. OSSIO’s development headquarters is located in Caesarea, Israel, and its commercial headquarters is in Woburn, Mass. (USA). For more information on the company, visit www.ossio.io.

Forward-looking statements contained herein are based on estimates and assumptions of OSSIO management and are believed to be reasonable, though they are inherently uncertain and difficult to predict.