VENTURA, Calif.--(BUSINESS WIRE)--Nexa3D, the maker of ultrafast polymer 3D printers, today announced the launch of its next generation membrane, Everlast-2 at RAPID + TCT 2021. Those attending the event, from September 13 to 15 at McCormick Place, Chicago, will be able to view the new Everlast-2 membrane in action and learn about its key features alongside Nexa3D’s expanding portfolio of ultrafast 3D printing products. Attendees can visit Nexa3D on booth E7428.

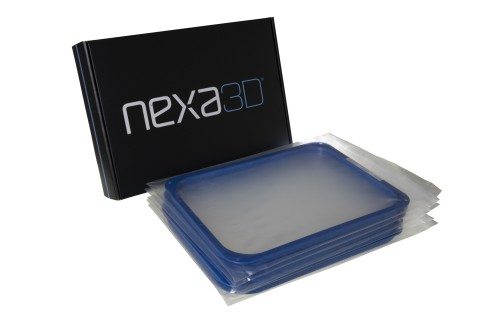

Nexa3D's Everlast Membrane offers superior print speed, surface finish and fidelity as well as tremendous functional durability, lasting 50,000 or more printed layers or some 25X longer than alternative interface layer technologies. Building on this success, Nexa3D now introduces Everlast-2, a new generation of interface layer technology that leverages the durability of Nexa3D’s Everlast Membrane to deliver enhanced printed part quality.

Everlast Membranes overcome the constraints of currently practiced alternative membrane technologies including clouding, chemical instability, and doming effects. Everlast-2 brings greater feature detail and smoother surfaces, alongside its added productivity benefits.

“Everlast-2 is the membrane of choice for customers that are more discerning about achieving greater printability performance without compromising speed, “explained Michele Marchesan, Chief Growth Officer of Nexa3D. Everlast-2 delivers greater feature definition and enhanced overall part smoothness. For customers who don’t want to spend precious time on part finishing — Everlast-2 shines.”

Everlast-2 is for all industries — any customer wanting to enhance the smoothness and consistency of their products can benefit. The improved fidelity and surface smoothness of parts reduces production times. It ties into Nexa3D’s suite of ultrafast technologies, which achieve 20X productivity savings while producing high-quality products with a minimal carbon footprint.”

Everlast Membranes are more durable, resilient, and deliver 25X the useful life of other vats and trays currently on the market. The Everlast Membrane exhibits consistent optical transmittance, so the 1000th produced part is identical to the first. It boasts a tough and resilient surface, enabling parts to be printed with previously unprintable technical materials. Everlast-2 is fully compatible with NXE 400 workflows and printing parameters, which include dynamic performance monitoring of the membranes with predictive usability feedback.

Everlast-2 is now available for purchase at nexa3d.com or through Nexa3D authorized resellers network. While customers will be impressed with this next generation membrane, the original Everlast Membrane will continue to be available for customers who prefer it. To learn more, check out this media kit and watch this video.

To view Nexa3D’s innovative products at RAPID + TCT, register here.

About Nexa3D

Nexa3D is passionate about digitizing supply chain sustainably. The company makes ultrafast polymer 3D printers, that deliver 20X productivity advantage, affordable for professionals and businesses of all sizes. The company partners with world-class material suppliers to unlock the full potential of additively manufactured polymers for volume production. The company makes automated software tools that optimize the entire production cycle using process interplay algorithms that ensure part performance and production consistency, while reducing waste, energy, and carbon footprints. For more information, please visit www.nexa3d.com.