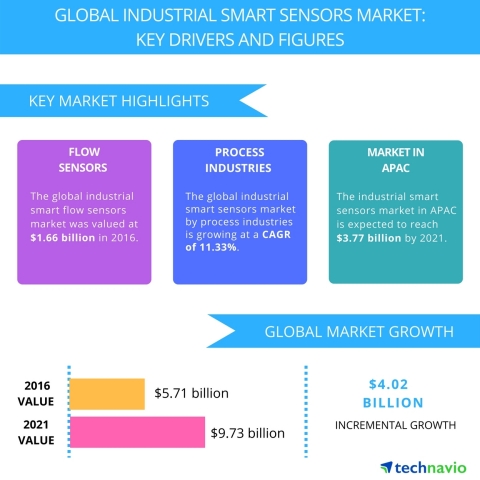

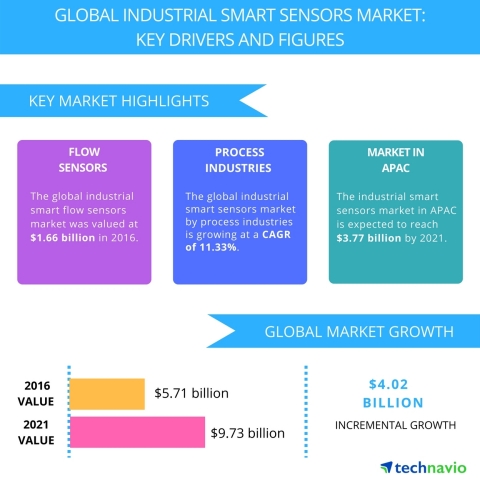

LONDON--(BUSINESS WIRE)--Technavio’s latest market research report on the global industrial smart sensors market provides an analysis of the most important trends expected to impact the market outlook from 2017-2021. Technavio defines an emerging trend as a factor that has the potential to significantly impact the market and contribute to its growth or decline.

The global industrial smart sensors market is expected to grow at a CAGR of more than 11% during the forecast period. These sensors are used in every phase of manufacturing, which helps in obtaining reliable and accurate real-time data. The industrial smart sensors cover varied applications such as smart cameras, smart helmets used in industries, sensors used in furnaces, and pressurized oil.

This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing

Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free.

The top three emerging market trends driving the global industrial smart sensors market according to Technavio research analysts are:

- Growing adoption of SoC in industrial smart sensors

- Implementation of IIoT

- Condition monitoring and diagnostics of industrial smart sensors

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

Growing adoption of SoC in industrial smart sensors

Industrial smart sensors are integrated with electronic components that perform functions such as data conversion, bi-directional communication, and taking decisions in an industrial set up. They are enabled with microprocessors that process all the acquired data and send it to control systems. Microprocessors used in these industrial smart sensors use an IIoT-enabled chipset for faster communication between the sensor devices and the control systems. There have been many developments in these chipsets.

According to Raghav Bharadwaj Shivaswamy, a lead analyst at Technavio for automation research, “One of the major developments in chipsets is the integration of sensors and other transduction elements together in one silicon chip; the complete system is called System-on-Chip. Some of the advantages of using SoC enabled industrial smart sensors are cost improvement, reduced costs of bulk cables and connectors, better signal to noise ratio, and system reliability.”

Implementation of IIoT

The implementation of IIoT is one of the key trends in all process and discrete industries. Industrial Internet of Things (IIoT) is a network of devices such as machines, sensors, controllers, big data analytics, and cloud computing components. Such integration would link analytics with the operations of industrial automation, which would ultimately improve the performance of the industry.

Currently, enterprise control systems such as PLC and SCADA are enabled with IIoT. These control systems need to communicate real-time data and store the data on the cloud after analyzing it. IIoT is a medium through which these control systems can perform the above functions. The inputs for these control systems are given by industrial smart sensors that sense information such as pressure, temperature, and health of workers. As industrial smart sensors are incorporated with microprocessors, they can process real-time data and send the data to control systems, which helps in avoiding accidents.

Condition monitoring and diagnostics of industrial smart sensors

Industrial smart sensors are generally mounted in the most active production areas and are highly exposed to surrounding effects. Due to the presence of dust, water, and vibrations, sensors require cleaning and maintenance to ensure reliable performance. Environment-related failures and the downtime associated with them should not occur when systems are working at a high level of production capacity. Solutions such as integrated diagnostics and self-test options can provide information regarding the presence of contamination.

“Industrial smart sensors with self-monitoring capabilities enable preventive maintenance to be carried out using a precise maintenance plan. The ability to predict machine status extends across area boundaries. For example, remote monitoring and remote maintenance provide a continuous way of identifying the areas that require maintenance. They also allow maintenance work to be performed during a scheduled machine downtime,” says Raghav.

Browse Related Reports:

- Global Industrial Visual Management Systems Market 2017-2021

- Global Variable Frequency Drives Market 2017-2021

- Global High-Pressure Valve Stem Seals Market 2017-2021

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 10,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

If you are interested in more information, please contact our media team at media@technavio.com.