LONDON--(BUSINESS WIRE)--Technavio’s latest report on the global plasma cutting machine market provides an analysis of the most important trends expected to impact the market outlook from 2017-2021. Technavio defines an emerging trend as a factor that has the potential to significantly impact the market and contribute to its growth or decline.

Plasma cutting machines are used in industries such as automotive, aerospace and defense, electrical equipment, industrial machinery, medical devices, and robotics to increase the simplicity and efficiency of high-precision product development. Due to globalization, there is a surge in demand for extremely accurate, high-quality products within a short duration of time. Plasma cutter can cut materials of different shapes and thicknesses. They deliver products with higher accuracy, precision, and speed and have minimal machine footprint when compared with mechanical cutting machines.

This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing

Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free.

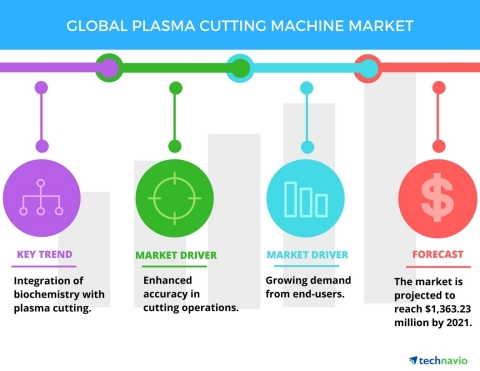

The top three emerging trends driving the global plasma cutting machine market according to Technavio heavy industry research analysts are:

- Integration of biochemistry with plasma cutting

- High-definition plasma cutting systems

- Technological developments in CNC solutions

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

Integration of biochemistry with plasma cutting

“The plasma cutting industry is witnessing a remarkable technological trend through the integration of biochemistry, which will impact the market significantly. For instance, LubeCorp, a Canadian company, offers fluid for treatment of the water on plasma cutting tables. The main objective of this fluid is to prevent the formation of rust and corrosion. It also efficiently biodegrades any bacteria that comes in contact with the cut parts. The company has assured that the fluid can be safely discharged as it does not have any harmful impact on the environment,” says Gaurav Mohindru, a lead analyst at Technavio for research on engineering tools.

The cut plates are immersed in the fluid, which forms a coating to provide the necessary protection. If the plates need to be processed further for painting or welding, the parts just need to be washed and cleaned to remove the coating.

High-definition plasma cutting systems

“The latest development in technology will ensure that all the parameters that control high definition class plasma are automated using CAM software and PC-based control systems. The electrical interfaces comprise Ethernet-based interfaces between the plasma, gas flow controller, torch height controller, and CNC system. Instant troubleshooting is available due to internal diagnostics. This can extend up to direct-to-factory connections to enable,” adds Gaurav.

High-definition plasma cutting systems addresses several intricate quality issues regarding the cut material. The lifespan of plasma consumable parts has increased because of the use of advanced gas flow and power supply control systems.

Technological developments in CNC solutions

The growing business competition emphasizes several organizations to move out from the traditional office environments and preferring to work from remote locations such as homes. It is estimated that a person on an average spends 40% of the time away from the desk. To achieve increased organizational productivity, several vendors are thereby developing Android-based CNC software solutions that allow the operator to control the machine from a mobile and transfer the programs for the machine’s operation remotely.

CNC solutions increase productivity besides using a minimal workforce. With globalization, several companies are effectively incorporating CNC solutions in the plasma cutting process. Machine builders are developing higher-resolution machines for faster productivity.

Browse Related Reports:

- Global Oil Mist Collector Market 2017-2021

- Global Home Electrical Consumables Market 2017-2021

- Global Foundry Tools Market 2017-2021

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 10,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

If you are interested in more information, please contact our media team at media@technavio.com.