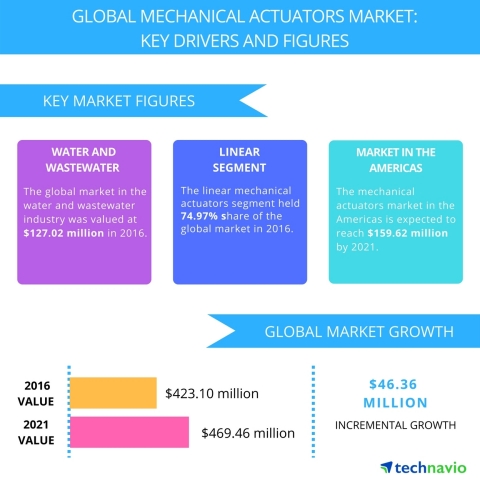

LONDON--(BUSINESS WIRE)--Technavio market research analysts forecast the global mechanical actuators market to grow at a CAGR of more than 2% during the forecast period, according to their latest report.

The market study covers the present scenario and growth prospects of the global mechanical actuators market for 2017-2021. The report segments the market by type into two major segments which are linear mechanical actuators and rotary mechanical actuators, of which the linear mechanical actuators segment held close to 75% of the market share.

This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing

Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free.

Technavio analysts highlight the following four market drivers that are contributing to the growth of the global mechanical actuators market:

- Low cost of mechanical actuators

- Capability of handling heavy loads and easy maintenance

- Growing focus of industries on green technology

- Increasing demand for linear mechanical actuators

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

Low cost of mechanical actuators

Mechanical actuators are very cheap when compared with other actuators, as they do not require pneumatic or hydraulic power to operate. They are usually manually or mechanically controlled. These actuators are available at low cost because of the low complexity of their system. They do not require hydraulic fluid or compressed air to operate, which, in turn, results in low cost of maintenance. On the other hand, pneumatic and hydraulic-powered actuators are not only expensive but can also lead to issues such as leakages.

Capability of handling heavy loads and easy maintenance

Mechanical actuators can be scaled for a wide range of applications in the discrete and process manufacturing industries. These actuators have the capability of handling heavy loads, and the amount of thrust capacity they generate depends on their size and rating. Mechanical actuators generate a thrust capacity of up to 200,000 pounds. The speed at which they operate depends on the load that they move, and the maximum speed that a mechanical actuator can attain is 50 inches per minute.

“Although wear and tear are common in any actuator, the maintenance of mechanical actuators is comparatively easy, as there is no need to change the hydraulic fluid used or compress the air. The area of applications of these actuators include load lifting mechanisms, mainly in the shipbuilding, water and wastewater treatment, and defense and aerospace industries,” says Raghav Bharadwaj Shivaswamy, a lead analyst at Technavio for automation research.

Growing focus of industries on green technology

Mechanical actuators help in conserving energy through avoiding the usage of electric, pneumatic, and hydraulic inputs, therefore, they embody green technology, which ensures no damage is caused to the environment.

The possibility of leakages makes hydraulic and pneumatic actuators agents of contamination, resulting in wastage of renewable energy. Mechanical actuators help avoid all such wastages and conserve energy, driving the growth of green technology.

Increasing demand for linear mechanical actuators

Linear mechanical actuators are more commonly used as compared to rotary mechanical actuators because of wide areas of application. These actuators convert rotary motion into linear motion, which is used in almost all the industries. These actuators are used in lifting mechanisms, seat actuation mechanisms, valve operating mechanisms, and door opening mechanisms.

Applications of lifting mechanism can be mostly observed in the shipbuilding, manufacturing, and heavy industries. Seat actuation mechanism is used in the automotive industry, valve operating mechanism in the water and wastewater treatment industry, and door opening mechanism in the aerospace and defense industry.

“To decrease the weight of the vehicle and increase fuel efficiency, the aerospace and defense industries are using low weight component parts in their vehicles, leading to the use of low weight actuators. This, in turn, is driving the demand for linear mechanical actuators, which weigh less than hydraulic and pneumatic actuators and do not require much space,” says Raghav.

Browse Related Reports:

- Global Hot Water Recirculation Pumps Market 2017-2021

- Global Valves Market in Mining Industry 2017-2021

- Global Industrial Enclosures Market 2017-2021

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 10,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

If you are interested in more information, please contact our media team at media@technavio.com.