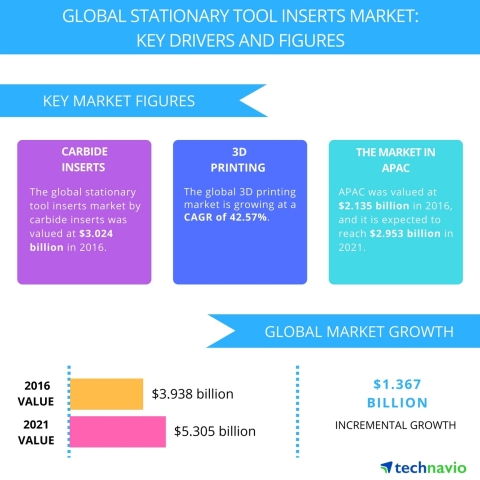

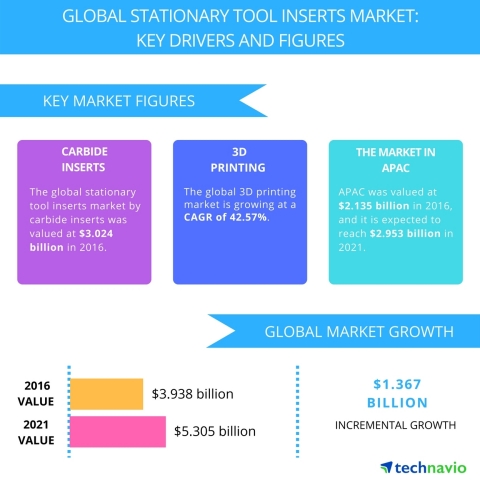

LONDON--(BUSINESS WIRE)--Technavio’s latest report on the global stationary tool inserts market provides an analysis on the most important trends expected to impact the market outlook from 2017-2021. Technavio defines an emerging trend as a factor that has the potential to significantly impact the market and contribute to its growth or decline.

Gaurav Mohindru, a lead analyst from Technavio, specializing in research on the tools and components sector, says, “Stationary tool inserts find application in almost every manufacturing industry. The key users of stationary tool inserts are automotive, aerospace, oil and gas, agricultural machinery, and other similar industries. The dynamics in these industries will impact the demand for stationary tool inserts globally.”

Automotive market dynamics will have a direct impact on the global stationary tool inserts market, as the automotive industry is one of the largest consumers of tool inserts. The growth in the overall global GDP is directly linked to the demand for vehicles. Rising regional tensions and the need for advanced weaponry will drive the growth of the aerospace segment. In western nations, where debt burdens continue to exert a downward pressure on governments' spending, defense budgets will remain relatively stable because of growing geopolitical tensions and the need to replace or modernize aging aircraft and weapons.

Request a sample report: https://www.technavio.com/request-a-sample?report=57421

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

The top three emerging trends driving the global stationary tool inserts market according to Technavio’s heavy industry research analysts are:

Additive manufacturing

The manufacturing industry has witnessed the advent of a revolutionary technology known as 3D printing, which is also known as additive manufacturing. 3D printing is a process of creating three-dimensional objects using a digital file. This process usually involves building the product in thin layers, one by one. 3D printing enables the production of complex geometries that are either arduous or impossible with traditional manufacturing techniques.

“The additive nature of 3D printing, unlike traditional printing technologies, optimizes the use of material and therefore minimizes wastage. Traditional techniques are subtractive in nature where the manufacturing takes place by cutting away the excess material,” according to Gaurav.

Growing market for high-speed tool inserts

HSS metal cutting tools are used by companies across various sectors such as automotive, aerospace, shipbuilding, die mold, part manufacturers, tool rooms, heavy industries, electrical, electronics, healthcare, oil and gas, energy, and consumer utilities. Companies are using these tools for increased ease and efficiency in the development of quality products.

Moreover, customers across the globe are insisting on superior-quality products in minimal production time and at a reduced cost. Therefore, several organizations have begun to deploy HSS metal cutting tools such as milling tools, drilling tools, tapping tools, reaming tools, counter-boring tools, broaching tools, and gear cutting tools.

Use of double-sided inserts for rough turning applications

The use of double-sided inserts for rough turning applications enhances process reliability. Such inserts add a ground contact surface with an optimized profile, which enables a protective layer to guard the insert against fracturing.

The double-sided insert finds its application in heavy interrupted cuts and forged parts with multiple machining depths, primarily in the roughing of steel materials. In addition, the double-sided insert provides double the standard number of cutting edges when compared with the single-sided insert.

The key vendors are as follows:

- Ingersoll Cutting Tool Company

- ISCAR

- Kennametal Foundation

- Northern American Carbide

- Sandvik

Browse Related Reports:

- Global Screw Machine Market 2017-2021

- Global Grinding Machinery Market 2017-2021

- Global Workholding Market 2017-2021

Become a Technavio Insights member and access all three of these reports for a fraction of their original cost. As a Technavio Insights member, you will have immediate access to new reports as they’re published in addition to all 6,000+ existing reports covering segments like construction, unit operations, and engineering tools. This subscription nets you thousands in savings, while staying connected to Technavio’s constant transforming research library, helping you make informed business decisions more efficiently.

About Technavio

Technavio is a leading global technology research and advisory company. The company develops over 2000 pieces of research every year, covering more than 500 technologies across 80 countries. Technavio has about 300 analysts globally who specialize in customized consulting and business research assignments across the latest leading edge technologies.

Technavio analysts employ primary as well as secondary research techniques to ascertain the size and vendor landscape in a range of markets. Analysts obtain information using a combination of bottom-up and top-down approaches, besides using in-house market modeling tools and proprietary databases. They corroborate this data with the data obtained from various market participants and stakeholders across the value chain, including vendors, service providers, distributors, re-sellers, and end-users.

If you are interested in more information, please contact our media team at media@technavio.com.