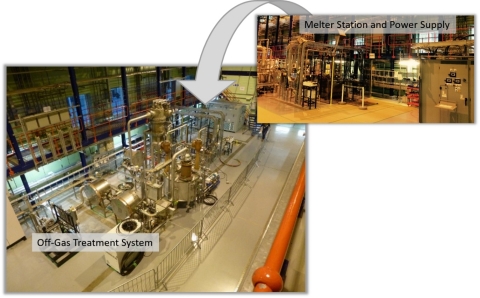

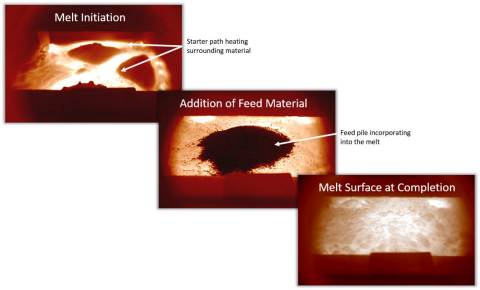

SELLAFIELD, England & IRVINE, Calif.--(BUSINESS WIRE)--The UK’s National Nuclear Laboratory (NNL) and Kurion announced their GeoMelt® In-Container Vitrification (ICV™) plant at NNL’s flagship Central Laboratory on the Sellafield site was operational and open for business after successfully completing its cold and active commissioning in June; the final milestone in their two-year collaboration. As a result, the team performed its first commercial melt last week by demonstrating the ability to treat corroded Magnox fuel sludge (simulated) mixed with contaminated soil for the UK Nuclear Decommissioning Authority (NDA).

Inactive and active tests were performed at the Central Laboratory as paid demonstrations for Sellafield, Ltd. (Sellafield) and the NDA as part of the system’s commissioning program. The last test of which was completed June 10, capping a commissioning program that included mockup testing at the NNL inactive Workington facility in November. In all cases, the system started up safely, reliably and achieved its design goals. The extensive commissioning program included pre-energized system checks, safety evaluations and integration of the experience gained over the 26,000 tonnes of glass that GeoMelt® has produced in the U.S., UK, Japan and Australia since the 1990s.

The UK Radioactive Waste Inventory lists over 300,000 tonnes of intermediate-level waste and low-level waste that could be suitable for thermal treatment with GeoMelt®. That is because GeoMelt® is uniquely capable of processing varied forms of waste simultaneously, enabling it to turn liabilities, such as contaminated soils and inorganic ion exchange media, into assets as glass formers. The technology is also capable of vitrifying and stabilizing radioactive contaminated asbestos, which can be found at many of the plants undergoing decommissioning. In contrast to other processes, GeoMelt® reduces the volume of waste and creates a superior, leach-resistant waste form that decreases packaging, storage, handling, transportation and disposal costs. As a result, it lowers the lifecycle costs for managing and dispositioning waste streams.

“Now open for business to demonstrate, test and process contaminated materials, the GeoMelt® system forms an important role in fulfilling our core mission. That mission is to evaluate options to improve the lifecycle cost for managing and dispositioning waste streams, including problematic waste streams that currently lack a path to disposal,” said Nick Hanigan, Customer and Delivery Director for the National Nuclear Laboratory. “Furthermore, this collaboration with Kurion brings together world-class scientists and engineers to accelerate the treatment of hazardous and radioactive waste.”

“We are proud to work with the UK’s National Nuclear Laboratory to install a GeoMelt® system at its Central Laboratory, which is an innovation center for developing solutions for radioactive waste around the world,” said John Raymont, founder of Kurion. “Leading decision makers from the U.S., Japan and Europe have come to respect the great work taking place at the NNL, and we intend to use this new system to demonstrate the effectiveness of GeoMelt® for applications across the worldwide nuclear market.”

In 2014 the NNL joined an agreement with the UK Nuclear Decommissioning Authority, U.S. Department of Energy’s Office of Nuclear Energy and its office of Environmental Management to collaborate on radioactive waste and nuclear materials cleanup and management.

ABOUT NNL

The UK’s National Nuclear Laboratory (NNL) offers a breadth of technical products and services covering the complete nuclear fuel cycle, from fuel manufacture and power generation to reprocessing, waste treatment and disposal. Most of our work is focused around our sites in the North West of England, and we are the second biggest industrial employer in West Cumbria.

With over 10,000 man years of nuclear experience across the fuel cycle, coupled with world-leading nuclear R&D facilities, we deliver the experts and technologies that ensure the UK nuclear industry operates safely, efficiently and cost effectively. For more information, please visit www.nnl.co.uk.

ABOUT KURION

Kurion creates technology solutions to access, separate and stabilize nuclear and hazardous waste to isolate it from the environment. The Kurion suite of technologies and engineering capabilities offer a platform to address the most-challenging waste sites worldwide. Founded in 2008, Kurion is a member of the Veolia Group, the global leader in optimized resource management. With over 174,000 employees worldwide and annual revenues of about €25 billion, the Veolia Group designs and provides water, waste and energy management solutions that contribute to the sustainable development of communities and industries. Kurion is headquartered in Irvine, Calif., and has facilities in Richland, Wash.; Idaho Falls, Idaho; Houston, Texas; Loveland, Colo.; Abingdon, UK; and Tokyo, Japan. For more information, please visit www.Kurion.com.