RÜSSELSHEIM, Germany--(BUSINESS WIRE)--"The market for virtual benchmarking is on the increase," affirms Jürgen Veith, member of the management board at Tecosim. The TEC|BENCH virtual benchmarking process forms the centre of Tecosim's presence at EuroCarBody, the international trade conference for vehicle body benchmarking in Bad Nauheim, Germany. Between 20 and 22 October, this specialist in computer-aided engineering (CAE) will be presenting its own take on reverse engineering. It will offer fresh options and potential based on its virtual benchmarking tool, which it has been developing further for over ten years.

The development-specific, technological framework conditions in automotive development are changing at a frenetic pace worldwide. An increasing variety of models and the capturing of niche markets are almost at odds with the desire for faster model changes and the use of innovative materials and substances. Benchmarking – comparing your own developments with standards in your sector – is an important means of saving time and costs as you respond to the challenge of rapid change.

More than ten years' experience in virtual benchmarking

The automotive industry expects further virtualisation of complex development steps to offer potential for such cost and time savings. With its self-developed benchmarking process TEC|BENCH, Tecosim presents a solution for virtual benchmarking which has proven its worth over many years. Specialised in computer-aided engineering (CAE), this engineering company commenced its business model for virtual product comparison over ten years ago and is showcasing the current further developed version of the process at this year's EuroCarBody.

From a single component to a complete vehicle in a predetermined development environment

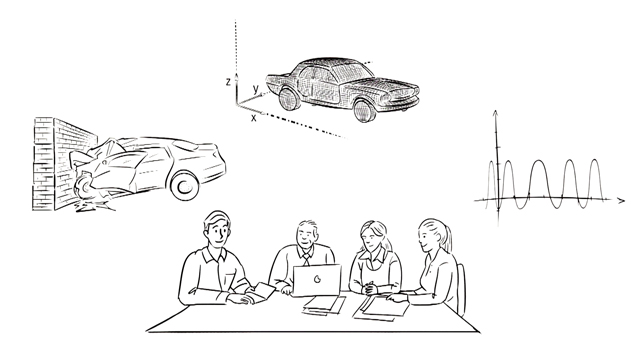

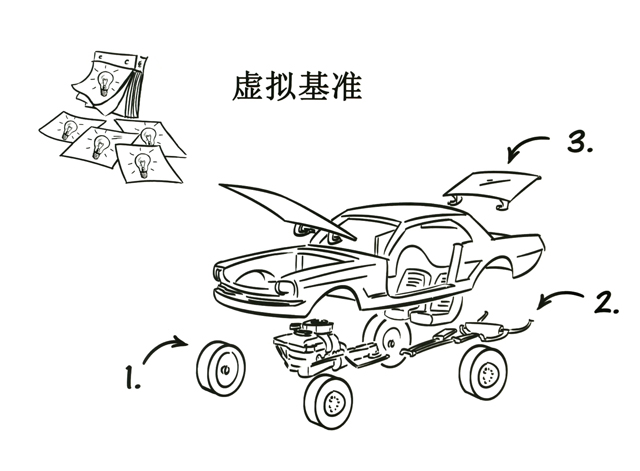

Each TEC|BENCH project seeks to produce a precise virtual reproduction based on a digital reconstruction of the original component or vehicle for the purposes of reverse engineering. The starting point is a detailed appraisal of a vehicle which is freely available on the market. In an initial step, different characteristics tests are carried out. The vehicle is then dismantled and the individual components scanned. After completing this hardware benchmarking, Tecosim transfers the knowledge it has acquired to a virtual simulation model, which is optimally adjusted to the client's development environment.

Simpler, faster optimisation in the early development stage

"TEC|BENCH not only enables Tecosim to provide virtual design and structural change to individual modules and complete vehicles, but also allows processing in the client's own environment," explains Martin Westerwald, the person responsible for TEC|BENCH who also points to the growing complexity of modern, multi-material designs. The client is able to complete a variety of cost-efficient comparison tests between their own digital prototypes and the model virtualised in TEC|BENCH. Tecosim thus allows a component or complete vehicle to be optimised during different stages of development.

Tecosim has completed numerous projects with TEC|BENCH to date and has established virtual benchmarking worldwide beyond the leading market of Germany, particularly in Asia. The company will be showcasing its products at Booth 17 at this year's EuroCarBody in Bad Nauheim, Germany.

You will find more information on the event here.

Tecosim Group company profile

Tecosim is a leading development partner in computer-aided engineering (CAE) on the global market. The specialist for numerical calculation and simulation employs a workforce of 400 worldwide. The internationally active group has its headquarters in Rüsselsheim, Germany, and is represented by six branches in Germany as well as its own subsidiaries in the UK, India and Japan. Tecosim provides support for customers in the transport, energy, health, industry and technology sectors. Engineers work on challenging tasks in structure simulation, computational fluid dynamics, multi-body simulation and system simulation. As a driver of innovation, Tecosim utilises trend-setting methods and provides comprehensive consultation services – from initial concepts through to all-in-one solutions ready for series production. The services on offer are made complete by software tools and process optimisation methods.