ALBUQUERQUE, N.M.--(BUSINESS WIRE)--CPFD Software, LLC:

Abstract

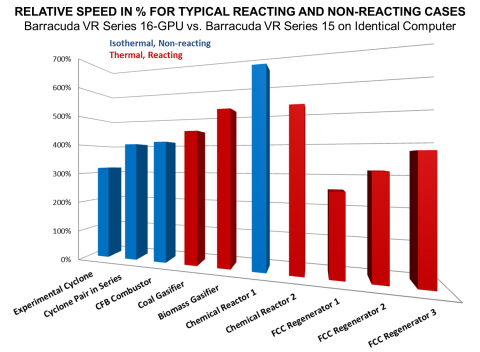

Barracuda Virtual Reactor® from CPFD Software, the world leader in fluidized bed reactor simulation software for CAE/CFD, is now available in a version highly parallelized to run on GPUs (graphical processing units), giving users a speed increase of up to 650%. This innovative use of low-cost GPU hardware means all users can now have a “desktop supercomputer” to deliver faster than ever the game-changing economic improvements Barracuda VR® models can enable in output, efficiencies, time-to-market, and emissions compliance across all segments of global process industries.

Barracuda VR Series 16-GPU enables HPC capability and builds on the value that more than 50 Global 500 manufacturers and technology licensors have already attained from CPFD’s proven CAE software package, which is unique in its ability to model 3D reacting flows within fluidized bed reactors (FBRs) and circulating fluidized bed (CFB) reactors. Owners of oil refineries, chemical plants, power generation / gasification plants, and polysilicon FBRs have optimized their reactors’ production rates and yields, increased reactor lifetimes, plus reduced emissions using this unique particle-flow CFD software.

Embraced by corporate and plant engineering teams and their contract service partners, Barracuda VR allows them to optimize all fluid, thermal and chemically reacting behavior inside a fluidized bed reactor (FBR). What sets Barracuda VR apart from more traditional, general-purpose CFD software is how it models individual, discrete particulate solids possessing any heterogeneous composition (e.g. coal, coked catalyst, polyolefins), and how it captures the entire particle size distribution for multiple solid species in detail. The complex 3D particle flows are fully-coupled to a user’s chemical reactions, thereby assuring accurate models of FBR behavior, AND with the new GPU-parallel HPC capability it is faster computationally than ever before.

According to Dr. Ken Williams, CPFD co-founder - “Oil refineries can potentially save $20-80 million per unit by avoiding capital equipment purchases through optimization of their FCC regenerator to comply with EPA MACT requirements. Barracuda VR with its new GPU-parallel has quite simply just enabled informed decision making for fluidized reactor optimizations and lifetime extensions, or with downselecting from complex design modifications.”

Ray Fletcher of Intercat Inc. (Subsidiary of Johnson Matthey and Barracuda user), states, “We are especially excited about the new particle-level chemistry capabilities in Barracuda VR. For the first time, this will enable modeling of the coke combustion chemistry in fluidized catalytic cracking (FCC) regenerators together with detailed fluid dynamics simulations. This models the spent catalyst combustion as it occurs in an operating unit. The new GPU-parallel capability in Barracuda VR greatly enhances our initiative to assist refiners in cost effectively meeting new EPA emissions requirements. Furthermore, this simulation occurs 400% faster, allowing Barracuda VR to be used to analyze FCC operations efficiently.”

About CPFD Software

Founded in 2006 by two pioneers in the field of computational fluid dynamics (CFD) modeling, CPFD Software, LLC, is privately held and headquartered in Albuquerque, New Mexico, USA and is the worldwide leader in CFD software for industrial fluidization reactors.

For the full-length Press Release, visit www.cpfd-software.com/gpunews