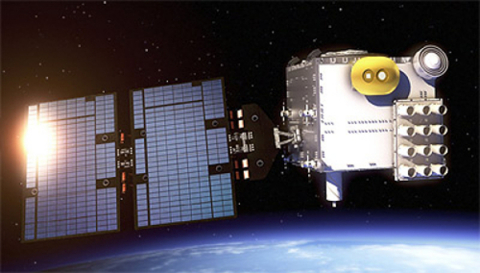

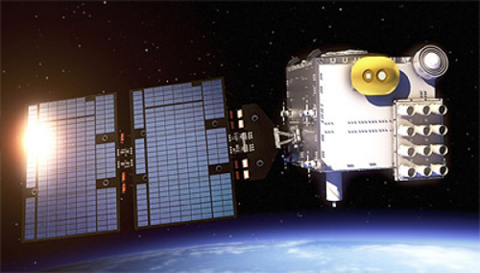

MINNEAPOLIS--(BUSINESS WIRE)--RedEye, a Stratasys Company (Nasdaq:SSYS) and leading provider of 3D printing and additive manufacturing services, has partnered with NASA’s Jet Propulsion Laboratory (JPL) to 3D print 30 antenna array supports for the FORMOSAT-7 Constellation Observing System for Meteorology, Ionosphere, and Climate (COSMIC-2) satellite mission.

Scheduled for launch in 2016, the COSMIC-2 mission marks the first time 3D printed parts will function externally in outer space. The antenna arrays will capture atmospheric and ionospheric data to help improve weather prediction models and advance meteorological research on Earth.

In order to keep the project on time and on budget, JPL needed an alternative to machining the parts out of astroquartz, the material traditionally used for the arrays. They turned to RedEye to produce 3D printed parts that could handle the complex array designs and also be strong enough to withstand the demands of outer space.

RedEye built the custom-designed parts using Fused Deposition Modeling (FDM), the only additive manufacturing process able to meet the project’s strength and load requirements. JPL chose durable ULTEM 9085 material, a thermoplastic that has similar strength to metals like aluminum but weighs much less.

“Using FDM for a project like this has never been done before and it demonstrates how 3D printing is revolutionizing the manufacturing industry,” said Jim Bartel, vice president and general manager at RedEye. “If this technology can be validated for use in the harsh environment of outer space, its capabilities are seemingly endless for projects here on Earth.”

While ULTEM 9085 has been well-vetted in the aerospace industry and is flammability rated by the Federal Aviation Administration (FAA), it has not previously been used or tested for an exterior application in space. The material passed qualification testing to meet NASA class B/B1 flight hardware requirements. To protect the antenna array supports against oxygen atoms and ultraviolet radiation, a layer of NASA’s S13G protective paint was applied to the parts.

“The intricate design of the arrays and the durability of ULTEM 9085 made additive manufacturing a perfect choice for this project,” said Joel Smith, strategic account manager for aerospace and defense at RedEye. “Not only did it prove the strength of 3D printed parts, but using FDM to build these supports significantly reduced time and cost.”

Learn more about how RedEye and JPL used FDM to build parts to meet these unique specifications by reading the case study.

About RedEye

RedEye, a

Stratasys Company, is one of the world’s leading providers of rapid

prototyping and additive manufacturing services. The company leverages

Stratasys’ patented FDM and PolyJet 3D printing processes to assist

companies in all phases of product development from conceptual modeling

to the production of end-use parts. RedEye has a network of more than

150 3D printers worldwide and has received awards for its services and

leadership. Stratasys recently acquired Solid

Concepts and Harvest

Technologies to combine with RedEye to form a leading advanced

manufacturing services organization, providing customers with access to

a broad range of additive and traditional technologies as well as

industry expertise. Online at: RedEyeOnDemand.com.

About Stratasys

Stratasys Ltd.

(Nasdaq:SSYS), headquartered in Minneapolis, Minnesota and Rehovot,

Israel, is a leading global provider of 3D printing and additive

manufacturing solutions. The company's patented FDM®,

PolyJet™, and WDM™ 3D Printing technologies produce prototypes and

manufactured goods directly from 3D CAD files or other 3D content.

Systems include 3D printers for idea development, prototyping and direct

digital manufacturing. Stratasys subsidiaries include MakerBot and

Solidscape, and the company operates a digital-manufacturing service,

comprising RedEye, Harvest Technologies and Solid Concepts. Stratasys

has more than 2500 employees, holds over 600 granted or pending additive

manufacturing patents globally, and has received more than 25 awards for

its technology and leadership. Online at: www.stratasys.com

or http://blog.stratasys.com.