iMFLUX Becomes First Injection Molding Technology to Receive Underwriters Laboratories (UL) Verification

iMFLUX Becomes First Injection Molding Technology to Receive Underwriters Laboratories (UL) Verification

HAMILTON, Ohio--(BUSINESS WIRE)--iMFLUX today announced that its injection molding technology has received Underwriters Laboratories (UL) Verification for three of the technology’s key sustainability advantages. UL Verification is an objective, science-based assessment that confirms the accuracy of marketing claims. UL has verified: “iMFLUX delivers up to 15% energy savings, up to 4% part weight reduction and automatically adapts to ± 52% MFI material shift.”

“A verification such as this ensures injection molding customers that iMFLUX will deliver key benefits related to their operational and sustainability objectives as they rethink strategies that enable the circular economy,” said Mary Wagner, iMFLUX CEO.

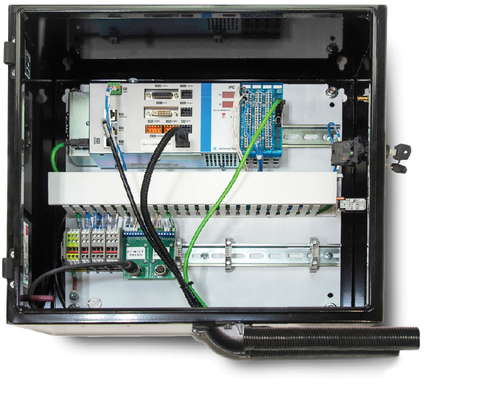

The iMFLUX system is comprised of software, pressure sensor and user interface to work on virtually any injection molding machine, material, or mold. iMFLUX’s adaptive process technology injects material into the mold at a low-constant-pressure via a closed loop feedback system. By turning iMFLUX on and switching from high pressure, decoupled processing to low-constant-pressure, an immediate energy savings is realized. The low-constant-pressure injection molding process fills the mold slowly to allow the material to cool, densify and pack-as-it-fills, also leading to lighter weight parts.

In addition, the iMFLUX system has an Auto Viscosity Adjust™ (AVA) feature. This feature allows for the seamless adjustment of the injection molding process to any source of variation recognized by the pressure sensor. Without operator adjustment the injection molding machine can automatically adapt to significant melt flow variations and continue to make quality parts.

Visit UL Verification to learn more

About iMFLUX

iMFLUX (a wholly owned subsidiary of Procter & Gamble) is a software and engineering innovation company that partners with leaders in the injection molding industry delivering significant, sustainable competitive advantage in their market segments. iMFLUX’s core technical competencies include polymer processing, machine control software and hardware, mold design and fabrication, materials expertise, metrology & analytics and industrial design. This unique combination of technical expertise all under one roof provides our customers with a one-stop solution to some of the most challenging engineering challenges the industry faces. www.imflux.com

Contacts

iMFLUX

Amy Brown

Brown.ab.2@imflux.com