HOUSTON--(BUSINESS WIRE)--The following is an opinion editorial provided by Larry Price, CEO, with Zilkha Biomass Fuels 1 LLC.

The DutchNews article regarding biomass-fired electricity plants from October 30, 2019 titled “Biomass-fired Electricity Plants Are On Balance More Polluting Than Coal: Report” is based on a flawed premise. The article attempts to oversimplify a complex process and is inaccurate with many of the facts. I am providing the following information as the basis for clarifying the benefits of biomass for energy generation for both heat and power.

Biomass is a term bantered about today as a single entity. There are many types of biomass and the energy produced from them varies based on how the material is treated after harvesting. Processed biomass – black pellets, white pellets, for example – has higher energy value than unprocessed biomass. The moisture levels are lower – typically, 5 – 10% for pellets versus 30 – 70% for untreated biomass, and the processed materials provide a replacement for coal in coal-fired power stations and reduce emissions while maintaining equivalent output of electricity. The goal is to pack as much biomass energy into a cubic meter as a piece of coal so that you can achieve optimum operations. Densified biomass pellets like the Zilkha BlackTM wood pellet achieve this goal.

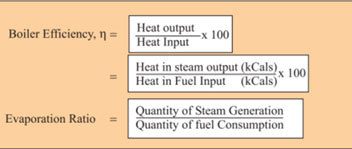

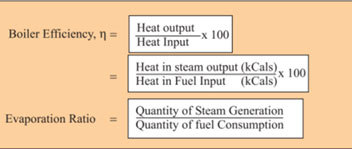

Boilers designed to run coal become inefficient when switched to natural gas or other materials with higher moistures. The boilers lose approximately 30% capacity when switched to natural gas – which, by the way is a fossil fuel. This loss of efficiency will lead to higher costs for the end users of electricity. The same loss of efficiency and higher costs are true for non-densified biomass fuels.

Broadly, biomass is organic material that comes from plants and animals and is a renewable source of energy. The CO2 cycle provides for conversion of CO2 to oxygen that is required to reduce emissions and reduce the strain they put on the planet. The “- 1.5 C” standard set by the United Nations is based on using this scientific cycle to reduce emissions and heal the environment.

The current situation world-wide focuses on reducing emissions on a country by country basis. Renewable energy is an important part of the process. The transition from a carbon-based heat and power system currently based on fossil fuels to one based on renewables is challenging. Solar and wind are components of “new generation” systems but neither are capable of meeting increased demands from consumers when the sun doesn’t shine or the wind doesn’t blow. Biomass is dispatchable – energy is stored in the fuel – and capable of providing us with clean electricity when we expect it.

The view of constituencies that oppose the use of biomass is to provide disinformation, deflecting the conversation without facts. Use of densified biomass wood pellets with energy values similar to steam coal, as a partial or total substitution for coal, provides emission improvements in total. An individual pollutant may increase slightly but the overall environmental process improves. In addition to improving emissions, biomass reduces the amount of ash produced in a boiler compared to differing grades of coal. Coal ash ponds are problematic in the US since alternative uses for the ash are limited due to the potential of groundwater intrusion. This may not be a problem in the rest of the world, however. Focusing on improvements utilizing biomass as a fuel still provides the environmental improvements needed to meet the goals we all are striving for now and in the future.

All densified biomass fuels are not the same. Black pellets have a minimum of 15% higher energy density compared to white pellets. They are capable of co-firing with coal without major modifications to the boiler fuel handling equipment at substitution rates of up to 50%. Minor costs are needed to modify the power stations to burn at a 100% rate. The higher energy stored in the pellets, coupled with not needing specialized storage systems provide benefits to the end user.

It is important for each of us to respond when we know the facts are wrong. Heat and Power producers, like RWE, continue to find realistic solutions that provide their customers with the electricity they need when the light switch is turned on. The public deserves to know the truth.

Zilkha Biomass Fuels I LLC is subsidiary of NextGen Black Pellets LLC and is headquartered in Houston, TX (USA)