COLUMBUS, Ohio--(BUSINESS WIRE)--Core Molding Technologies, Inc. (NYSE MKT:CMT), a leading North American compounder of custom sheet molding compound (SMC) and molder of fiberglass reinforced thermoset and thermoplastic compounds, today announced a breakthrough ultra-low density SMC formulation and an addition to Core’s industry-leading suite of low-density composite product offerings.

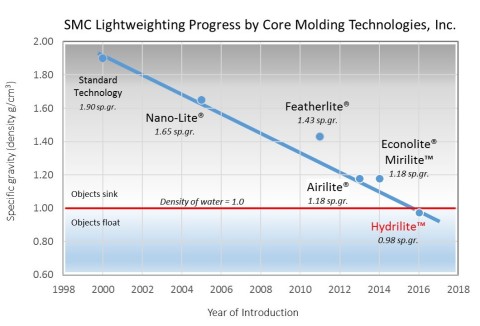

Core’s new, ultra-low density Hydrilite ™ SMC has a nominal density of 0.98 sp.gr. while exhibiting mid-range mechanical performance and a high-quality surface appearance. The achievement places the SMC system below the density of water and below most thermoplastic systems. The breakthrough represents a nearly 50% reduction from standard-density SMC materials and a 17% reduction from Core’s industry-leading lightweighting material solutions that include the commercially-successful Airilite® and Econolite® SMC systems that test at 1.18 sp.gr.

“Across our markets, customers continue to challenge us to lower the density of fiberglass reinforced material systems to support their lightweighting efforts,” said Terry O’Donovan, vice president, marketing and sales for Core Molding Technologies. “A density of 1.0 sp.gr., equivalent to the density of water, has long been seen as a practical limit by formulation chemists throughout the thermoset industry,” O’Donovan added. “To be the first to crack that barrier and achieve a functional system at 0.98 sp.gr. is a high achievement for our development team and a meaningful product advance for our customers.”

Hydrilite™ SMC is formulated with a high-performance resin system and is reinforced with 41% glass fiber by weight. “The use of glass fiber results in a material system considerably more economical than those based on carbon fiber, while achieving even lower density,” O’Donovan said. Hydrilite™ SMC achieves nominal tensile strength of more than 75 MPa and impact strength of 850 J/m. Both results are on par with Core’s standard-density reinforcement-grade SMC formulations. This performance, along with other mechanical properties of the system, make it ideal for a broad range of lightweighting applications requiring a combination of strength and high appearance. A commercial program using Hydrilite™ SMC is undergoing customer qualification, and other applications are in development.

“Hydrilite™ SMC is a significant advance in lightweighting performance,” O’Donovan said. “A molded product that weighs 100 pounds in standard-technology SMC, would weigh only 51 pounds in Hydrilite™ SMC. Yet, Hydrilite™ is probably not the stopping point. We are currently working to develop a full Class A version of the product, while retaining the 0.98 sp.gr. density and adequate mechanical performance. With an ongoing need for lightweighting solutions, no doubt our customers will continue to request further reductions in density, which we will strive to achieve,” O’Donovan stated.

Evaluation plaques and material performance data for Hydrilite™ SMC are available to qualified customers.

ABOUT CORE MOLDING TECHNOLOGIES, INC.

Core Molding Technologies, Inc. is a manufacturer of sheet molding compound (SMC) and molder of fiberglass reinforced thermoset and thermoplastic materials. Core specializes in large-format moldings and offers a wide range of fiberglass processes, including compression molding of SMC, glass mat thermoplastics (GMT) and bulk molding compounds (BMC); compression and transfer molding of direct long-fiber thermoplastics (D-LFT); spray-up, lay-up, resin transfer (RTM) and vacuum resin transfer molding (V-RTM). Additionally, the company offers reaction injection molding (RIM) of dicyclopentadiene (DCPD). Core serves a wide variety of markets, including the medium and heavy-duty truck, marine, automotive, agriculture, construction and other commercial products markets. Headquartered in Columbus, Ohio, Core maintains plants in Columbus and Batavia, Ohio; Gaffney, South Carolina; Winona, Minnesota; and Matamoros, Mexico. For further information, visit the company’s website at www.coremt.com.

This press release may contain certain forward-looking statements within the meaning of the federal securities laws. As a general matter, forward-looking statements are those focused upon future plans, objectives or performance as opposed to historical items and include statements of anticipated events or trends and expectations and beliefs relating to matters not historical in nature. Such forward-looking statements involve known and unknown risks and are subject to uncertainties and factors relating to Core Molding Technologies’ operations and business environment, all of which are difficult to predict and many of which are beyond Core Molding Technologies’ control. Words such as “may,” “will,” “could,” “would,” “should,” “anticipate,” “predict,” “potential,” “continue,” “expect,” “intend,” “plans,” “projects,” “believes,” “estimates,” “confident” and similar expressions are used to identify these forward-looking statements. These uncertainties and factors could cause Core Molding Technologies’ actual results to differ materially from those matters expressed in or implied by such forward-looking statements.

Core Molding Technologies believes that the following factors, among others, could affect its future performance and cause actual results to differ materially from those expressed or implied by forward-looking statements made in this report: business conditions in the plastics, transportation, marine and commercial product industries (including slowdown in demand for truck production); federal and state regulations (including engine emission regulations); general economic, social and political environments in the countries in which Core Molding Technologies operates; safety and security conditions in Mexico; dependence upon certain major customers as the primary source of Core Molding Technologies’ sales revenues; efforts of Core Molding Technologies to expand its customer base; the ability to develop new and innovative products and to diversify markets, materials and processes and increase operational enhancements; the actions of competitors, customers, and suppliers; failure of Core Molding Technologies’ suppliers to perform their obligations; the availability of raw materials; inflationary pressures; new technologies; regulatory matters; labor relations; the loss or inability of Core Molding Technologies to attract and retain key personnel; the Company’s ability to successfully identify, evaluate and manage potential acquisitions and to benefit from and properly integrate any completed acquisitions; federal, state and local environmental laws and regulations; the availability of capital; the ability of Core Molding Technologies to provide on-time delivery to customers, which may require additional shipping expenses to ensure on-time delivery or otherwise result in late fees; risk of cancellation or rescheduling of orders; management’s decision to pursue new products or businesses which involve additional costs, risks or capital expenditures; and other risks identified from time-to-time in Core Molding Technologies’ other public documents on file with the Securities and Exchange Commission, including those described in Item 1A of the Company’s 2015 Annual Report to stockholders on Form 10-K.