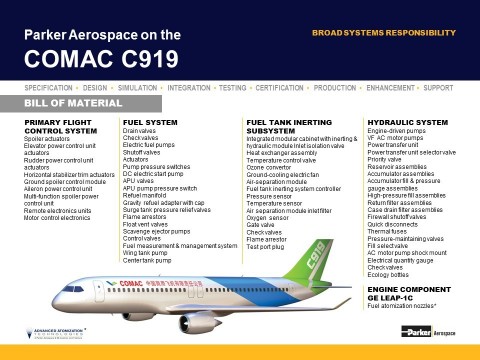

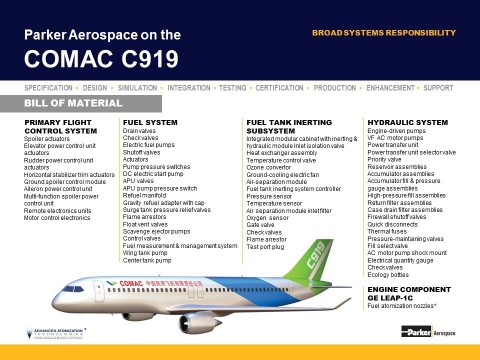

FARNBOROUGH, England--(BUSINESS WIRE)--Parker Aerospace, a business segment of Parker Hannifin Corporation (NYSE: PH), the global leader in motion and control technologies, is providing all of the key fluidpower, inerting, and motion control systems on the new C919, supporting COMAC as the platform prepares for flight testing. Parker is providing the three independent hydraulic systems, primary flight control system including the horizontal tail trim system, fuel gauging and management system, fuel tank inerting system, and landing gear conveyance. Additionally, it will provide fuel nozzles for the aircraft’s CFM LEAP-1C turbofan engines.

A total of more than 60 types of components make up Parker’s systems and subsystems on the C919. All have been conformity processed and safety-of-flight qualified prior to the aircraft’s overall flight testing, which is scheduled to begin later this year.

Parker was the first supplier to have completed full endurance spectrum testing, demonstrating that the integrated systems can deliver operational performance as required for the life of the airplane. In addition, the C919 AC motor pumps are part of an ongoing new development and design program, positioning Parker for further platform opportunities in the future.

Hydraulics system on the C919

The Parker Aerospace Hydraulic Systems Division (HSD) is providing the complete hydraulic system on the new COMAC C919 platform. The main components include engine-driven hydraulic pumps, AC motor pumps, power transfer units, reservoirs, filter modules, accumulators and ground service panels. Additionally, the hydraulic system features a control and monitoring software package for the C919 integrated modular avionics controller, also provided by Parker. Some of the mechanical components are provided by Parker’s joint venture partner on the C919, the AVIC Nanjing Engineering Institute of Aircraft Systems (NEIAS) and its suppliers AVIC Xinhang.

These components are installed in the three independent hydraulic systems on the aircraft and provide fluidpower for all flight control actuation, landing gear retraction and extension, nose-wheel steering, and thrust reverser deployment. All 20 types of the key hydraulic system components provided by Parker have been conformity processed and are qualified for flight.

“Parker HSD has been recognized as a number-one supplier to COMAC on the C919 and the ARJ-21 by completing total parts and subsystems conformity processing, quality documentation and review,” noted Chad Vliek, senior program manager for Parker’s Hydraulics Systems Division. “Parker has established itself within China as a leader in defining and responding to the customer’s total systems performance requirements.”

Fuel delivery and inerting systems on the C919

The Parker Aerospace Fuel Systems Division (FSD) is supplying the fuel delivery and fuel tank inerting systems on the C919. The fuel system consists of the following subsystems and functions: fuel tank vent, refuel and defuel, engine and APU feed, fuel transfer, fuel and water scavenge, and fuel quantity indication. The fuel tank inerting system (FTIS) consists of the following subsystems and functions: conditioned air supply, inert gas generation, and nitrogen enriched air (NEA) distribution.

Primary flight control system on the C919

The Parker Aerospace Control Systems Division (CSD) is providing state-of-the-art fly-by-wire subsystems including horizontal stabilizer trim actuation and motor control electronics, and aileron and elevator actuators with remote electronic units (REUs) for precise closed loop actuation control and system real-time monitoring. Parker also provides the REUs for control of the rudder and spoiler actuators, which are supplied by joint venture partner AVIC Flight Automatic Control Research Institute (FACRI).

Landing gear conveyance systems on the C919

Parker Aerospace is providing the landing gear conveyance system for the C919, featuring Stratoflex hoses and fittings, electrical airing and brackets, and associated mounting hardware in an integrated package.

LEAP-1C turbofan engines nozzles on the C919

Parker Aerospace is providing fuel nozzles and manifolds on the LEAP-1C turbofan engines that will power the C919. The state-of-the-art fuel nozzles are designed with low-NOx and low-CO fuel atomization technology, which is key to the development and operation of more fuel efficient and environmentally friendly engines such as the LEAP-1C.

Joint ventures

To reinforce Parker’s leadership position for COMAC aircraft systems, subsystems, and components, Parker Aerospace has established two joint ventures in China.

Working with the AVIC Jincheng Nanjing Engineering Institute of Aircraft Systems (NEIAS) the joint venture, NEIAS Parker Aero Systems Equipment (NPASE), was founded to provide engineering, manufacturing, assembly, and testing for fuel supply and management, fuel tank inerting, hydraulic power products and service, and final assembly and tests for the C919 and for other Chinese domestic aircraft products (such as the MA700). The joint venture also features a center-of-excellence machining center with a special processing shop.

The joint venture with AVIC Flight Automatic Control Research Institute (FACRI) in China, Parker FACRI Actuation Systems, is providing engineering support, final assembly, and tests for C919 products and for other Chinese domestic aircraft products (such as the MA700). The joint venture also features a FAA 145 and CAAC 145 certified maintenance, repair, and overhaul (MRO) shop that services flight control, hydraulic, and other Parker Aerospace products.

“With the key systems developed and supplied on the ARJ21 and the joint-venture involvement with the development and supply of all the major systems on the COMAC C919, Parker Aerospace has been recognized as a gold and silver supplier for our efforts over nine years,” noted Pui Ho, Parker’s vice president and regional manager of Asia Pacific. “As a result of our significant investment, especially in the two joint ventures, we feel that we are well positioned with extensive in-country manufacturing and testing to service and support our customers for their current aircraft platform programs of today and into the future for the long term.”

About Parker Aerospace. Parker Aerospace is a global leader in the research, design, manufacture, and service of flight control, hydraulic, fuel and inerting, fluid conveyance, thermal management, lubrication, and pneumatic systems and components for aerospace and other high-technology markets. Its product lines include primary and secondary flight control actuation, power generation and control components, thrust-reverser actuation systems, electrohydraulic servovalves, electric motor-driven hydraulic pumps, fuel pumps and valves, refueling, defueling, and aerial refueling equipment, fuel tank inerting systems; tank pressure and vent controls, level and flow control equipment; motor-operated valves and fuel equipment, lubrication oil reservoirs, lubrication and scavenge pumps, fuel measurement and management systems, thermal management products, cockpit instrumentation, lightning-safe products, pneumatic subsystems and components, water subsystems and components, fluid metering delivery and atomization devices, wheels, brakes, and fluid conveyance products such as hoses, tubes, disconnects, and fittings. It is an operating segment of Parker Hannifin Corporation.

About Parker Hannifin.

With annual sales of approximately $13 billion in fiscal year 2015, Parker Hannifin is the world's leading diversified manufacturer of motion and control technologies and systems, providing precision-engineered solutions for a wide variety of mobile, industrial, and aerospace markets. The company has operations in 50 countries around the world. Parker has increased its annual dividends paid to shareholders for 59 consecutive years, among the top five longest-running dividend-increase records in the S&P 500 index. For more information, visit the company's web site at www.parker.com, or its investor information web site at http://www.phstock.com.