LONDON--(BUSINESS WIRE)--Technavio’s latest report on the global coating pre-treatment market provides an analysis of the most important trends expected to impact the market outlook from 2017-2021. Technavio defines an emerging trend as a factor that has the potential to significantly impact the market and contribute to its growth or decline.

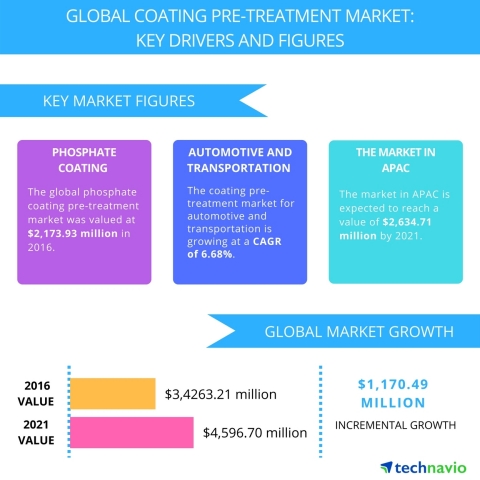

The research study by Technavio on the global coating pre-treatment market for 2017-2021 provides a detailed industry analysis based on the product type (phosphate, chromate, blast clean, and chromate-free), end-users (automotive and transportation, general industry, and consumer goods and appliances), and geography (APAC, Europe, North America, and ROW).

Coating pre-treatment is the process of removing contaminants from the metal surface and modifying the surface to a non-conductive one. The surface of the substrate is cleaned and modified to provide better adhesion and corrosion resistance. Technavio analysts forecast the global coating pre-treatment market to grow to USD 4,596.7 million by 2021, at a CAGR of more than 6% over the forecast period.

This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing

Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free.

The top three emerging trends driving the global coating pre-treatment market according to Technavio chemicals and materials research analysts are:

- Increasing use of zirconium

- Increasing sol-gel technology coatings

- Mergers and acquisitions

Increasing use of zirconium

Phosphates are being gradually replaced by zirconium due to its environment-friendly features. The weight of the zirconium and zinc phosphate varies from 145-200 mg/sq ft. Regardless of light weight, zirconium coatings provide better corrosion resistance and adhesion. This process results in phosphate-free and metal-free deposits on the surface of the metal.

“The zirconium coatings do not require heating, which stands as an advantage for energy savings. Due to lesser heating stages and lower maintenance, the cost can be reduced by approximately USD 105,000 every year. These advantages of zirconium have resulted in its preference in the market,” says Mohd Shakeel Iqbal, a lead analyst at Technavio for paints, coatings, and pigments research.

Increasing sol-gel technology coatings

Hybrid silicon alkoxides molecules are known for their coupling properties between the metal substrate and organic materials and are used in the production of sol-gel coatings. These molecules are hybrid molecules that are designed to bond both metal substrate and the organic coatings simultaneously.

The application of the sol-gel pre-treatment coating is carried out by the dipping procedure. The thickness of the coatings depends on the fluid thickness, viscosity, and withdrawal speed. The adhesion and corrosion properties are better when compare with the traditional pre-treatment processes. The preference to use this coating on aluminum and hot-dip galvanized (HDG) steel will significantly impact the market growth.

Mergers and acquisitions

“The key market players such as PPG Industries and BASF have adopted the mergers and acquisitions strategy to expand and increase the market share in the highly fragmented global coatings pre-treatment market,” says Shakeel.

For instance, BASF acquired Albemarle’s global surface treatment business, Chemetall, a leading developer and manufacturer of customized technology and system solutions for surface treatment. Similarly, PPG Industries has announced that the company would acquire the remaining interest in Chemfil Canada, a joint venture of PPG and Madinal Enterprises. This acquisition is likely to boost the pre-treatment presence and capabilities of PPG Industries in Canada and its pre-treatment services for global automotive OEM.

Browse Related Reports:

- Global Corrosion Inhibitors Market 2017-2021

- Global Masterbatch Market 2017-2021

- Global Ink Additives Market 2017-2021

Become a Technavio Insights member and access all three of these reports for a fraction of their original cost. As a Technavio Insights member, you will have immediate access to new reports as they’re published in addition to all 6,000+ existing reports covering segments like specialty chemicals, glass and ceramics, and industrial gases. This subscription nets you thousands in savings, while staying connected to Technavio’s constant transforming research library, helping you make informed business decisions more efficiently.

About Technavio

Technavio is a leading global technology research and advisory company. The company develops over 2000 pieces of research every year, covering more than 500 technologies across 80 countries. Technavio has about 300 analysts globally who specialize in customized consulting and business research assignments across the latest leading edge technologies.

Technavio analysts employ primary as well as secondary research techniques to ascertain the size and vendor landscape in a range of markets. Analysts obtain information using a combination of bottom-up and top-down approaches, besides using in-house market modeling tools and proprietary databases. They corroborate this data with the data obtained from various market participants and stakeholders across the value chain, including vendors, service providers, distributors, resellers, and end-users.

If you are interested in more information, please contact our media team at media@technavio.com.